MAB17 - NEMA17 Brake

|

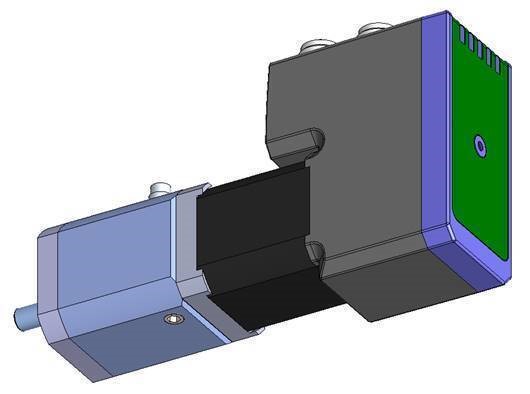

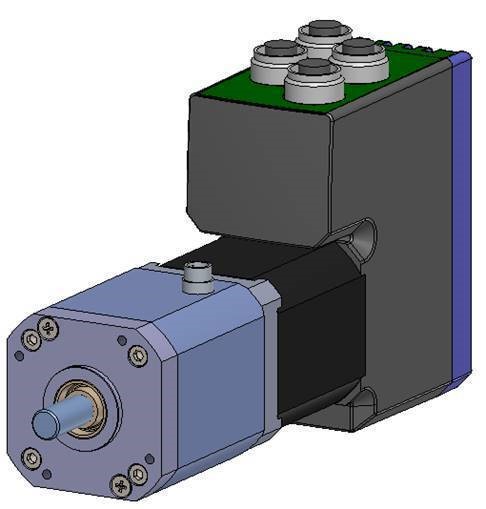

Electronic brake for all NEMA17 motors.

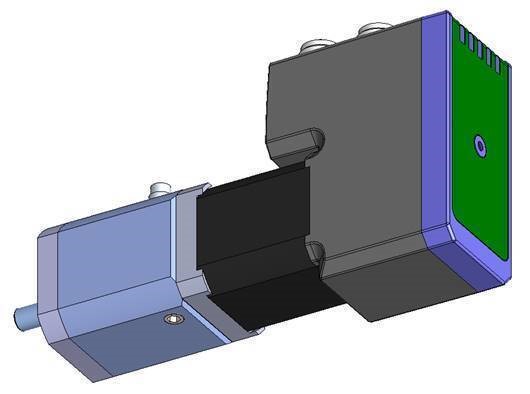

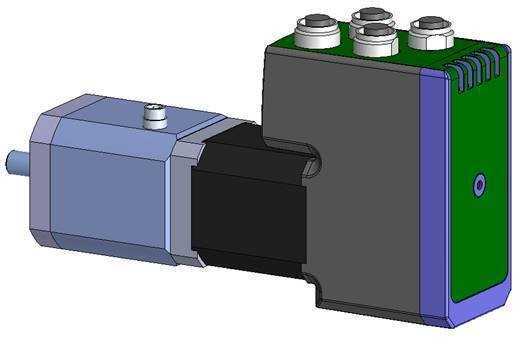

The electronic brake is designed to be mounted on step- and servo motors with NEMA17 flange 42x42mm. Brake itself have NEMA17 mounting dimension but flange size is 46x46mm. Brake can be mounted directly on stepper motor from JVL MST17x and also JVL integrated stepper motor MIS171, MIS173, MIS176 with 5, 6.35 and 8mm shaft. Brake can also be used on any other brand motor that use NEMA17 standard and have 5 , 6.35 and 8mm shaft. Output shaft can be 5 or 8mm. Shaft collars ring with 1 screw is used to tighten brake on motor shaft.

A high quality 24VDC electro-magnetic spring brake is mounted inside the housing. The brake use hub connection to brake disc so it can be mounted on motors with axial play. Holding torque is 0.5 to 0.7 Nm. The brake is used when it is desired to hold the motor shaft fixed at power off, or when the motor is used in a vertical linear application. When 24 VDC is connected, the brake will be deactivated and the motor can turn freely. It is only recommended to use the brake only as a holding brake and not as an emergency brake.

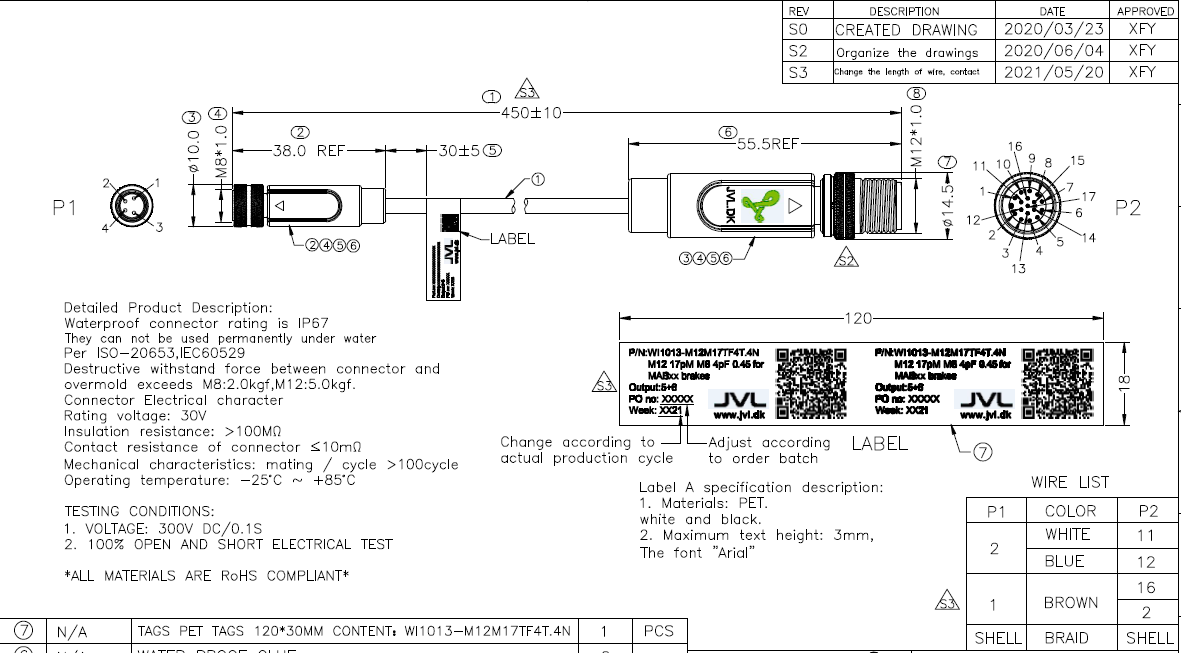

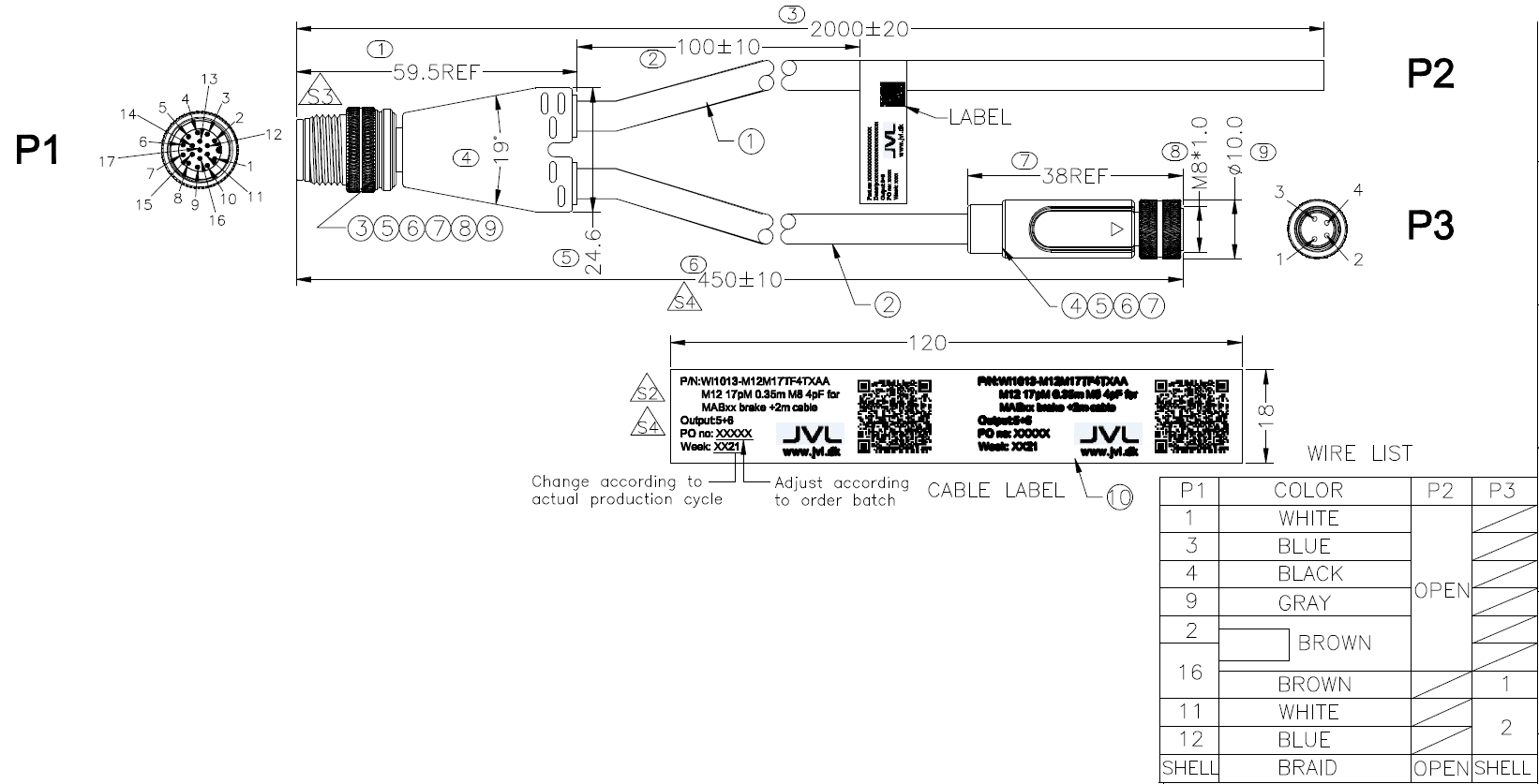

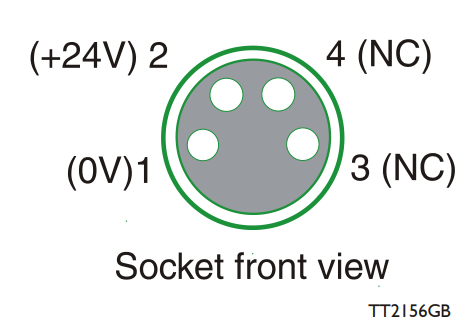

All brake are equipped with M8 4 pin male connector for 24V control voltage. |

|

|

|

|

|

|

|||||

|

|||||

|

|

|||||

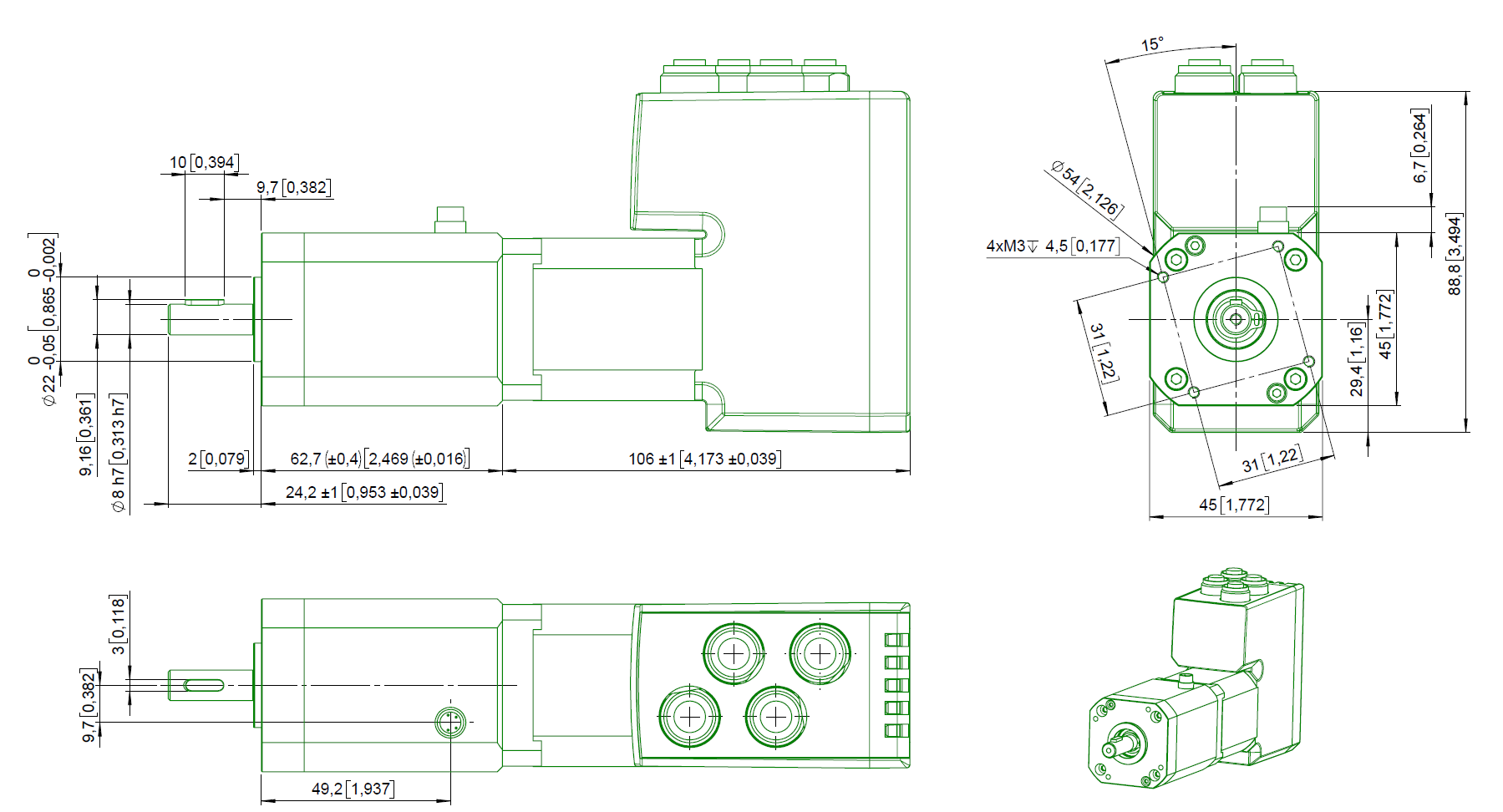

| Brake part number |

Input shaft (Note 1) |

Output shaft | Protection grade |

|

Length | Photo |

| MAB17M-.50NX2F35 | 8 mm round / 24 mm deep | 8 mm with key / 24 mm long | IP42 | 0.39 Kg | 62.7 mm |  |

| MAB17M-.50NX2FX4 | 8 mm round / 24 mm deep | 8 mm with key / 24 mm long | IP65 | 0.39 Kg | 62.7 mm |

|

| MAB17M-.50NX2F16 | 8 mm round / 24 mm deep | 5 mm round / 20 mm |

IP42 | 0.39 Kg | 62.7 mm |  |

| MAB17M-.50NX2F01 |

8 mm round / 24 mm deep | 6.35 mm D-cut / 20 mm |

IP42 |

0.39 Kg | 62.7 mm |  |

| MAB17M-.50N01F16 |

6.35 mm round / 24 mm deep | 5 mm round / 20 mm |

IP42 |

0.39 Kg | 62.7 mm |  |

| MAB17M-.50N01F35 |

6.35 mm round / 24 mm deep | 8 mm with key / 24 mm long |

IP42 |

0.39 Kg | 62.7 mm |  |

Note 1: Order sleeve HSHS17G08M-M05M for 5mm input shaft. Order sleeve HSHS17G08M-M06J for 6.35mm input shaft.

Note 2: All brakes with M8 4 pin male connector.

For recommended torque for shaft collar screw please read this document

| MAB17x | |

| Holding torque Nm | 0.5 to 0.7* |

| Backlash degree | <3 |

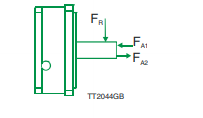

| Radial load Fr [N] | 300 |

| Axial load Fa1 | Motor ball bearing |

| Axial load Fa2 [N] | Motor ball bearing |

| Inertia [Kgcm3] 53 mm long | 0.049 |

| Inertia [Kgcm3] 57 mm long | 0.049 |

| On time [ms] | 10 |

| Off time [ms] | 40 |

| Current @24 VDC [A] | 0.175 |

| Power @24 VDC [W] | 4.2 |

| Pull in voltage [V] | >16 |

| Drop-out voltage [V] | <3.5 |

*Contact JVL for selected brake with >0.6 Nm.

| Accessories | Part number | Photo |

| Sleeve 5.0 to 8.0 mm | HSHS17G08M-M05M |  |

| Sleeve 6.35 to 8.0 mm | HSHS17G08M-M06J |   |

| Sleeve 5.0 to 6.35 mm | HSHS17G06J-M05M

|

|

| Shaft sealing IP65 | MO0216 | |

| O-ring between brake and motor | MO0033 | |

| Cable M8 female angle 5m. Pin 1:blue (0VDC), Pin 2 Brown (24VDC) , Pin 3 and 4 (NC) |

WI1000-M8F4A05N |  |

| Cable M8 female angle 10m. Pin 1:blue (0VDC), Pin 2 Brown (24VDC) , Pin 3 and 4 (NC) |

WI1000-M8F4A10N |  |

For more shaft bushings, adapters, sleeves click here.

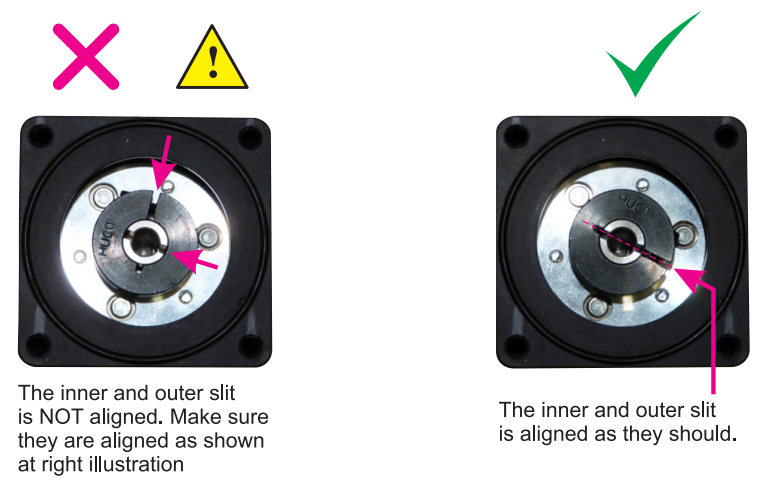

1: Motor clamp in correct position where shaft slit and collar slit are alligned.

2: Mount brake on motor.

3: Pull brake shaft to outer position.

4: Tighten the 4pcs M3 flange screws with low torque <0,1Nm

5: Tighten the clamp collar screw M2.5 with 2Nm

6: Tighten the 4 pcs M3 flange screws with torque 4 to 5Nm

Special NEMA 17 brakes

| Special front mounted brake part number |

Input HUB shaft diameter |

Output shaft | Protection grade |

|

Length | Photo |

| MAB17M-.50V03FAA | 10 mm | Not possible. Brake Hole 9 mm | IP00 | 0.2 Kg | xx mm |  |

| MAB17M-.50VX5FAA | 8 mm | 8 mm (Brake Hole 9 mm) |

IP00 | 0.2 Kg | xx mm |

|

| MAB17M-.50V01FAA | 6.35 mm | 6.35 mm (Brake Hole 9 mm) |

IP00 | 0.2 Kg | xx mm |  |

| MAB17M-.50V16FAA | 5 mm | 5 mm (Brake Hole 9 mm) |

IP00 | 0.2 Kg | xx mm |  |

All brakes with 300mm wire.

Cables

Brake cable connector and wires:

Pin 1 blue = 0 VDC, Pin 2 brown = +24 VDC, Pin 3 black = NC, Pin 4 white = NC.

Brakes with cable:

The wires comming from a brake can be mounted directly and there are no direction for those.

( There are no plus or minus connection. )

|

DETAILED |

|

|

|

DOWNLOAD |

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk