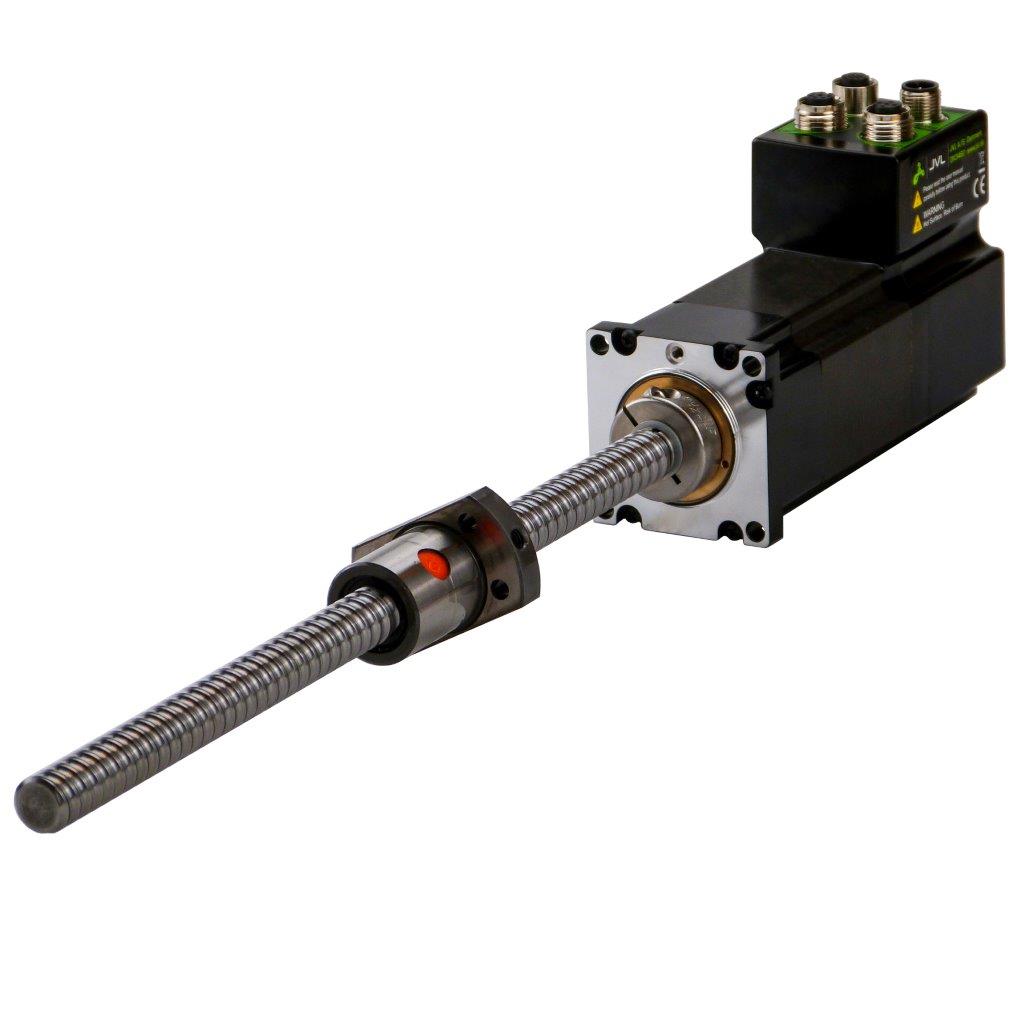

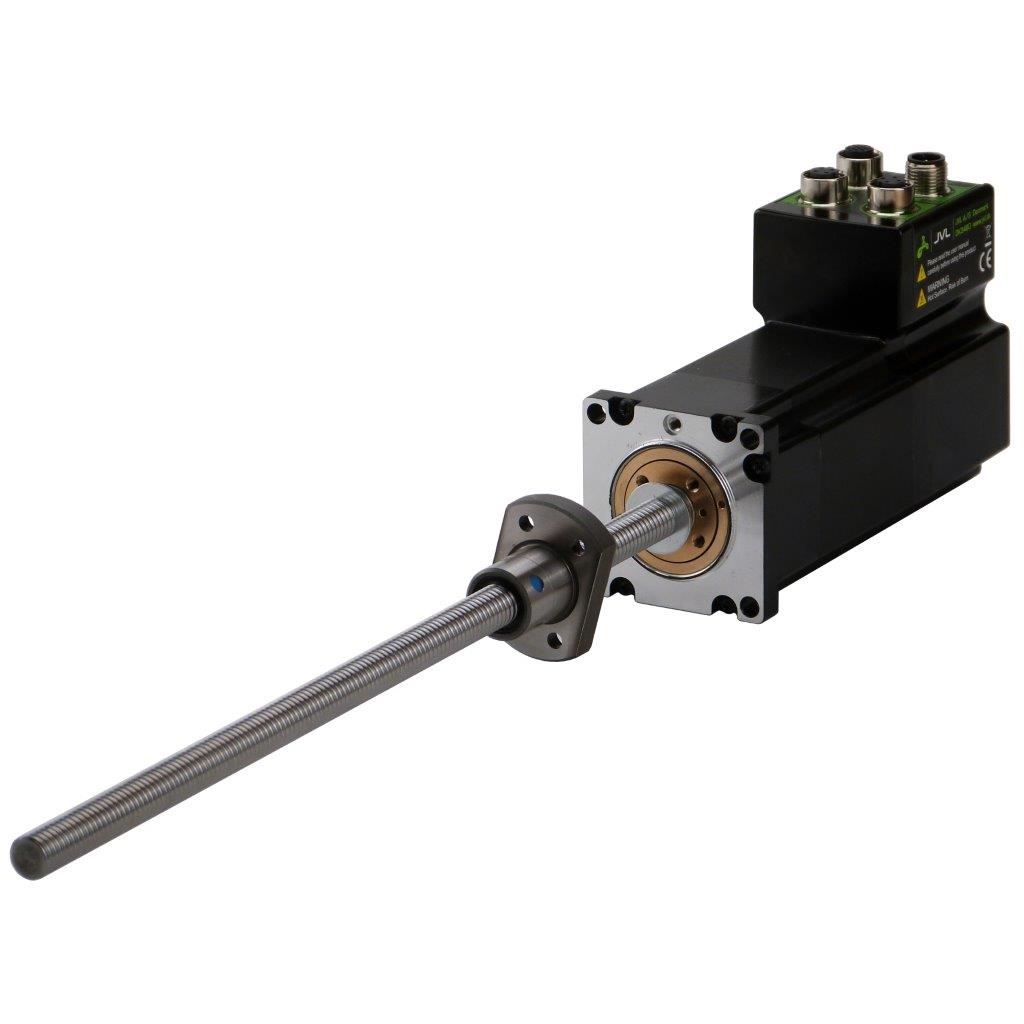

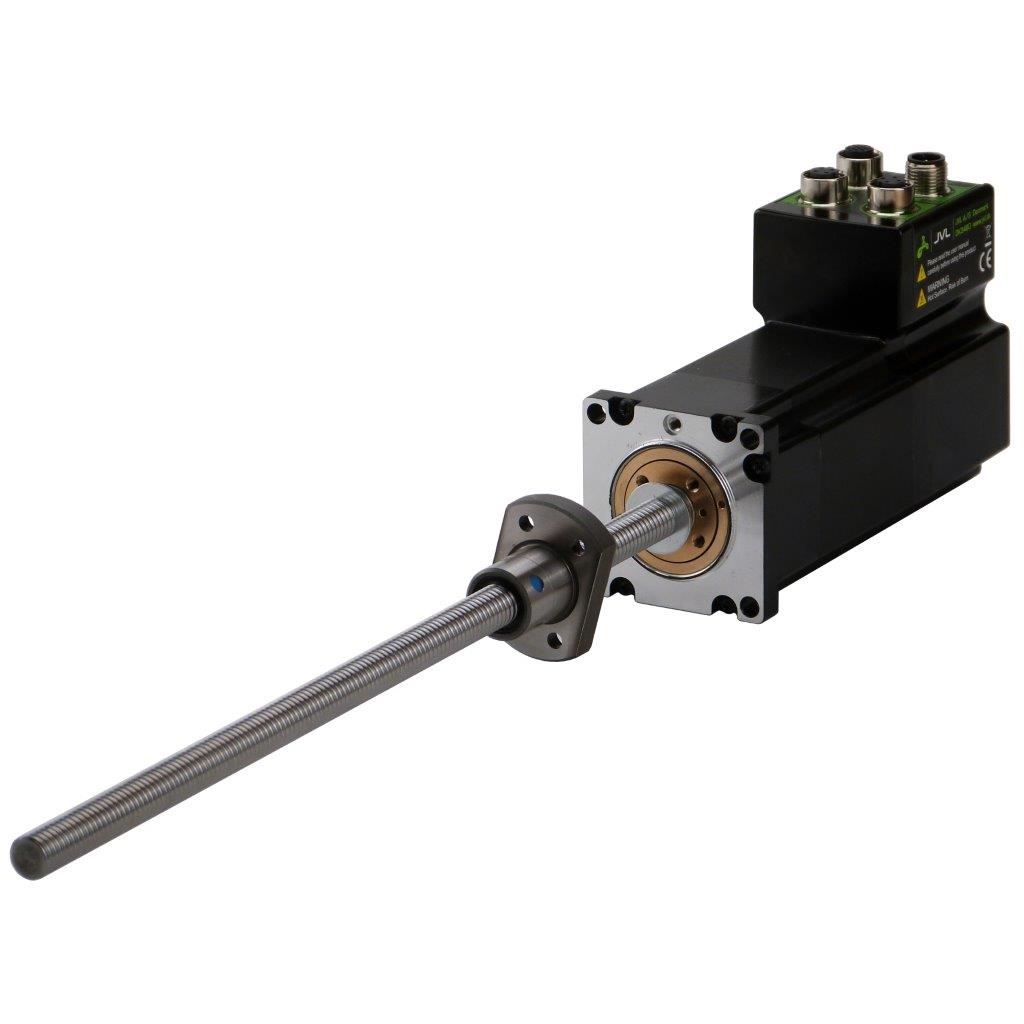

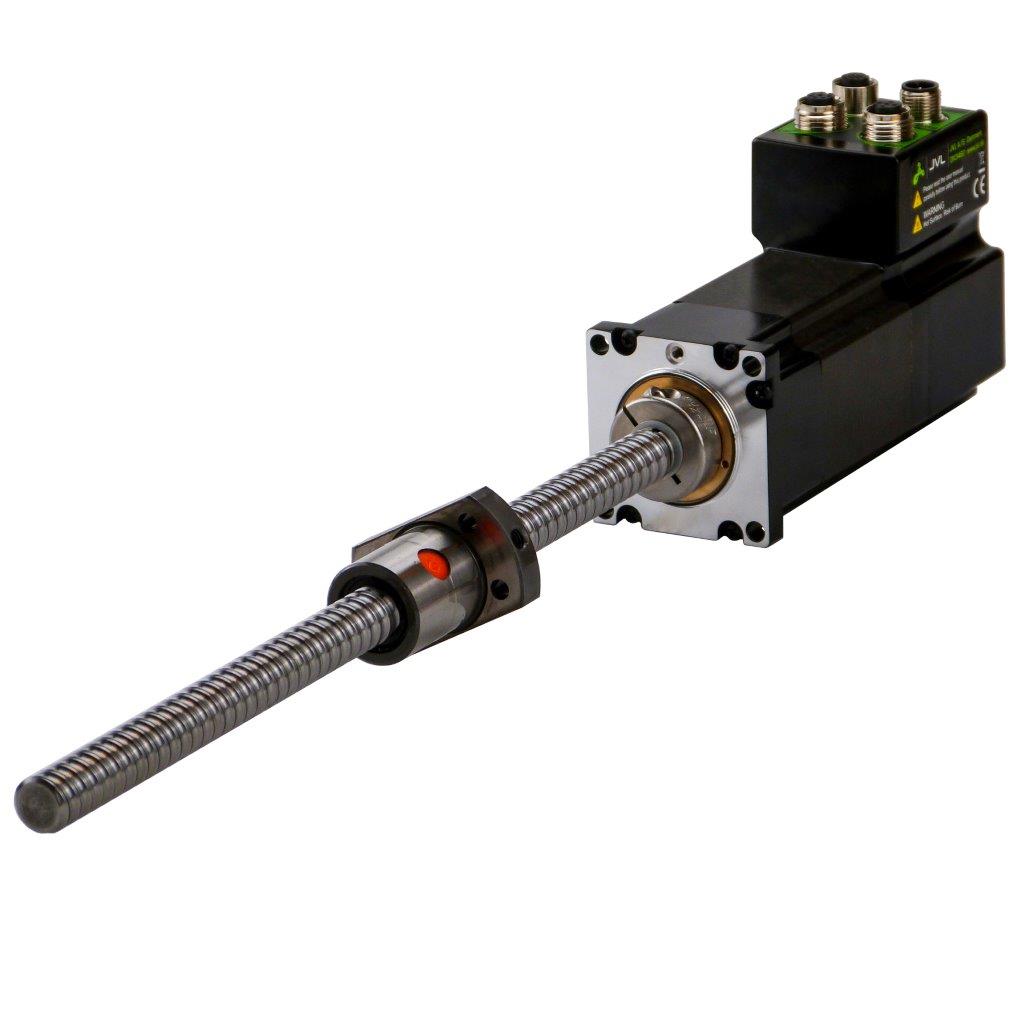

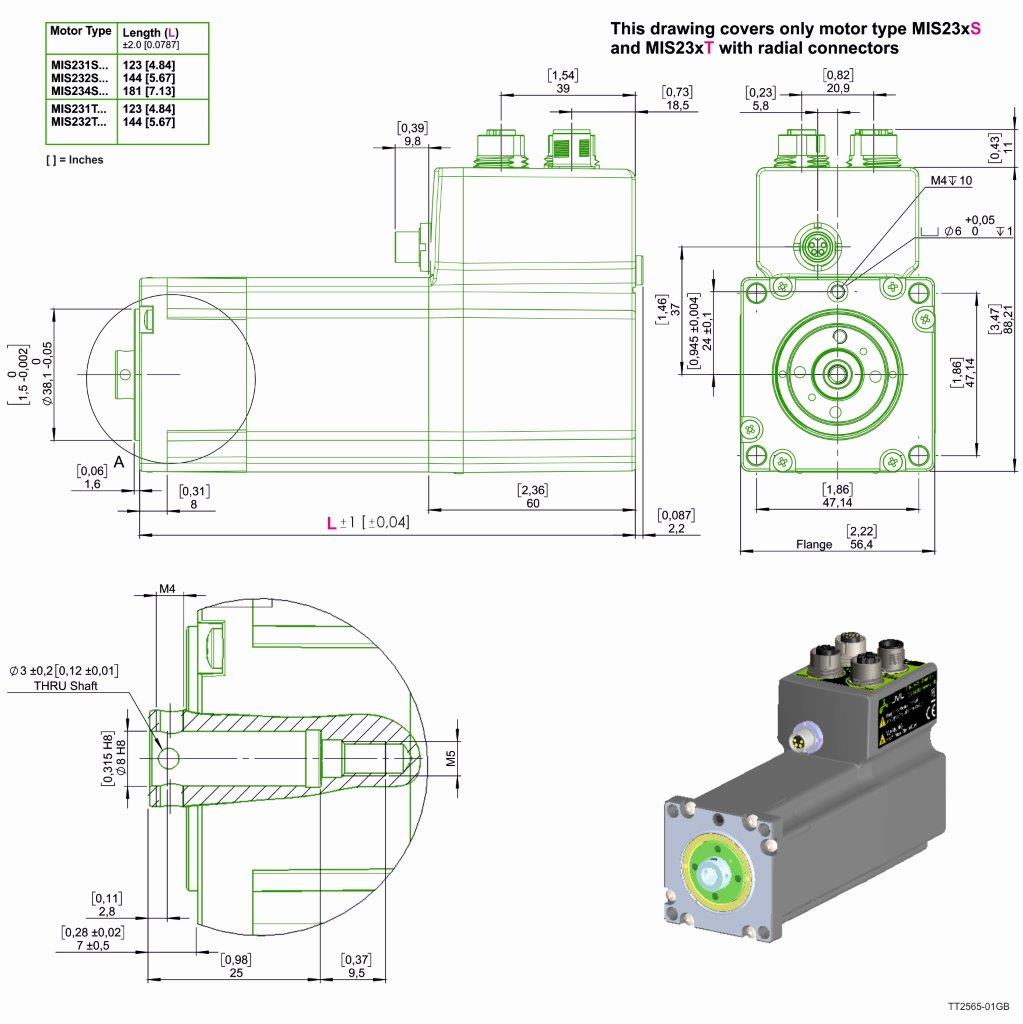

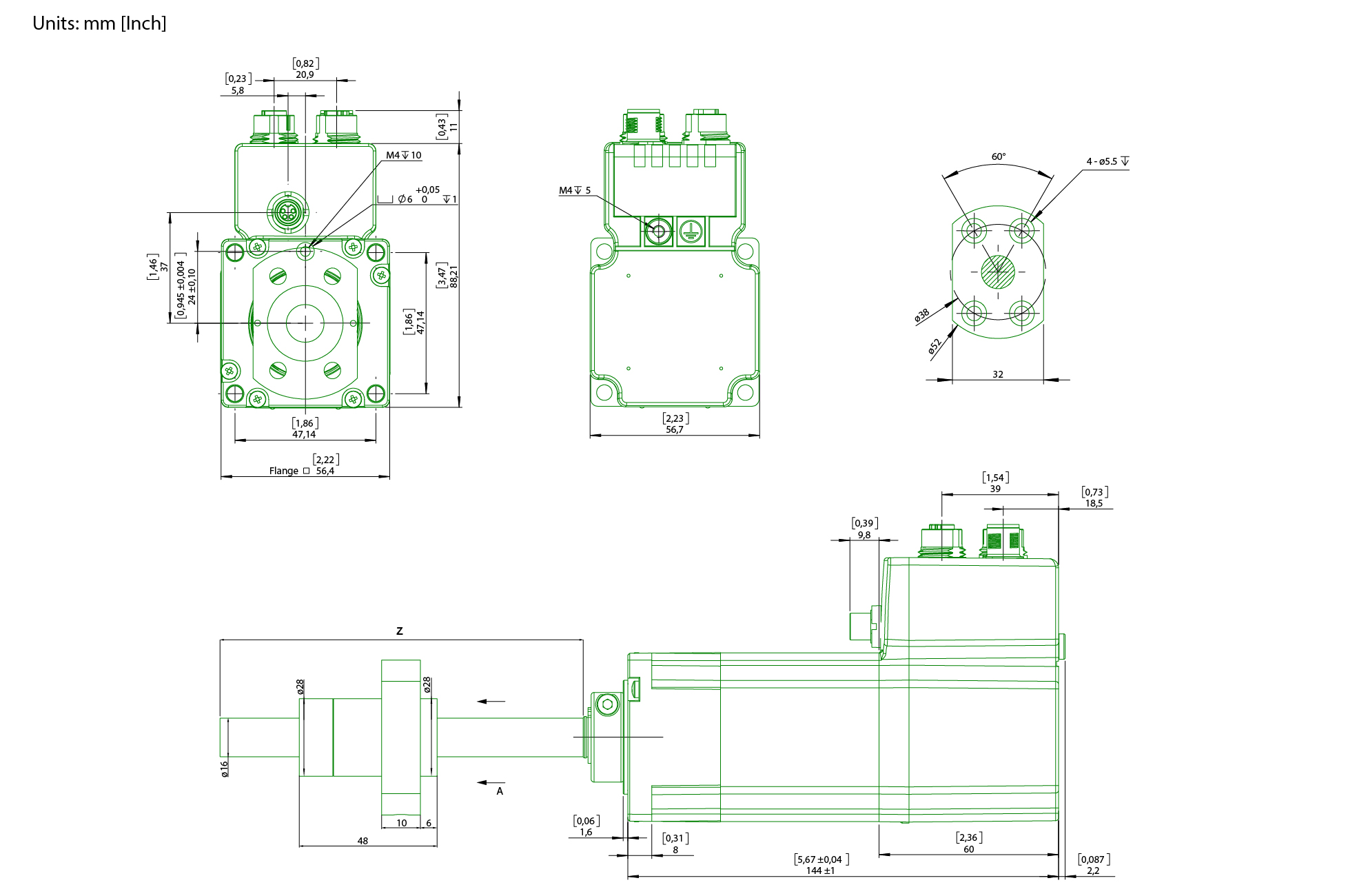

MIL23xS/W Integrated Stepper Motor Linear Actuator - NEMA23 Programmable with Closed-Loop, Ethernet, multiturn encoder

|

|

|

|

|

|

||

|

|||||||

| Motor Type |

Type |

Screw Diameter [mm] |

Screw Lead [mm] | Travel length [mm] | Screw length [mm] | Motor Length [mm] |

Weight [kg] |

| Motor with pin |

|||||||

| MIL232SBH-xxHy66H* |

Rolled ball screw |

12 |

2 |

270 |

300 |

144 |

1.55 |

| MIL232SBR-xxHy66L* |

Rolled ball screw |

12 |

5 |

570 |

600 |

144 |

1.55 |

| MIL232SCA-xxHy66A |

Captive |

15 |

0.635 |

12.7 |

12.7 |

144 |

1.60 |

| MIL232SCY-xxHy66C* |

Captive |

15 |

12.7 |

25.4 |

25.4 |

144 |

1.60 |

| MIL232SCY-xxHy66L |

Captive |

15 |

12.7 |

127 |

127 |

144 |

1.70 |

| Motor with clamp (easy-to-swap screws) |

|||||||

| MIL232WBR-xxHy66H* |

Rolled ball screw |

16 |

5 |

252 |

300 |

144 |

1.65 |

xx = Q5: PLC IO EC: EtherCat, EL: Powerlink, EI: EtherNet/IP, EP: Profinet, ES: Sercos, EM: MODBUS TCP

y = 2 : Incremental single turn encoder, 4: Absolute multiturn encoder

* = Preferred model

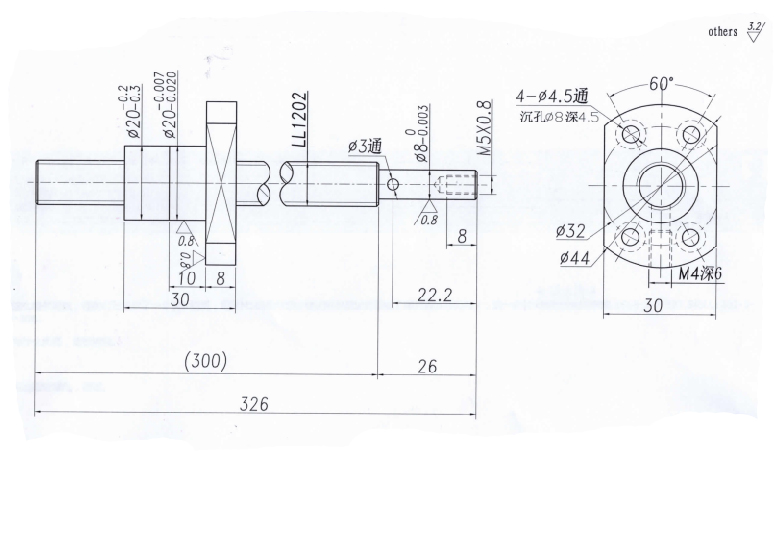

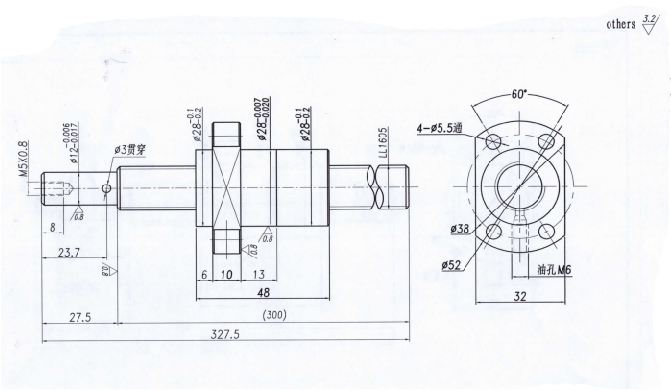

| MIL232S - ø12 mm with pin |

MIL232W - ø16 mm with clamp |

|

|

|

|

|

|

|

|

|

Force vs. Speed:

For MIL232S - Ball screw

For bigger projects we can offer the following Lead and screw length (MOQ. 10 pcs)

| Motor type |

Diameter [mm] |

Lead [mm/rev] |

Nut type |

Max. Length [m] |

| MIL232SBH.. (pin) |

12 |

2 |

Rolled ball screw (30 mm length) |

2.5 |

| MIL232SBM.. (pin) |

12 |

4 |

Rolled ball screw (30 mm length) |

2.5 |

| MIL232SBR.. (pin) |

12 |

5 |

Rolled ball screw (30 mm length) |

2.5 |

| MIL232SBW.. (pin) |

12 |

10 |

Rolled ball screw (30 mm length) |

2.5 |

| MIL232WBM.. (clamp) |

16 |

4 |

Rolled ball screw (48 mm length) |

3 |

| MIL232WBR.. (clamp) |

16 |

5 |

Rolled ball screw (48 mm length) |

3 |

| MIL232WBW.. (clamp) |

16 |

10 |

Rolled ball screw (48 mm length) |

3 |

Standard screw lengths JVL can deliver, if special length is required please contact JVL directly (MOQ 10 pcs.)

|

Code

|

Screw Length

[mm] |

Travel

Length ø12 screw

[mm] |

Travel

Length ø16 screw

[mm]

|

| A |

50 |

20 |

2 |

| B |

75 |

45 |

27 |

| C |

100 |

70 |

52 |

| D |

125 |

95 |

77 |

| E |

150 |

120 |

102 |

| F |

200 |

170 |

152 |

| G |

250 |

220 |

202 |

| H |

300 |

270 |

252 |

| I |

350 |

320 |

302 |

| J |

400 |

370 |

352 |

| K |

500 |

470 |

452 |

| L |

600 |

570 |

552 |

| M |

700 |

670 |

652 |

| N |

800 |

770 |

752 |

| O |

900 |

870 |

852 |

| P |

1000 |

970 |

952 |

| Captive lead screw |

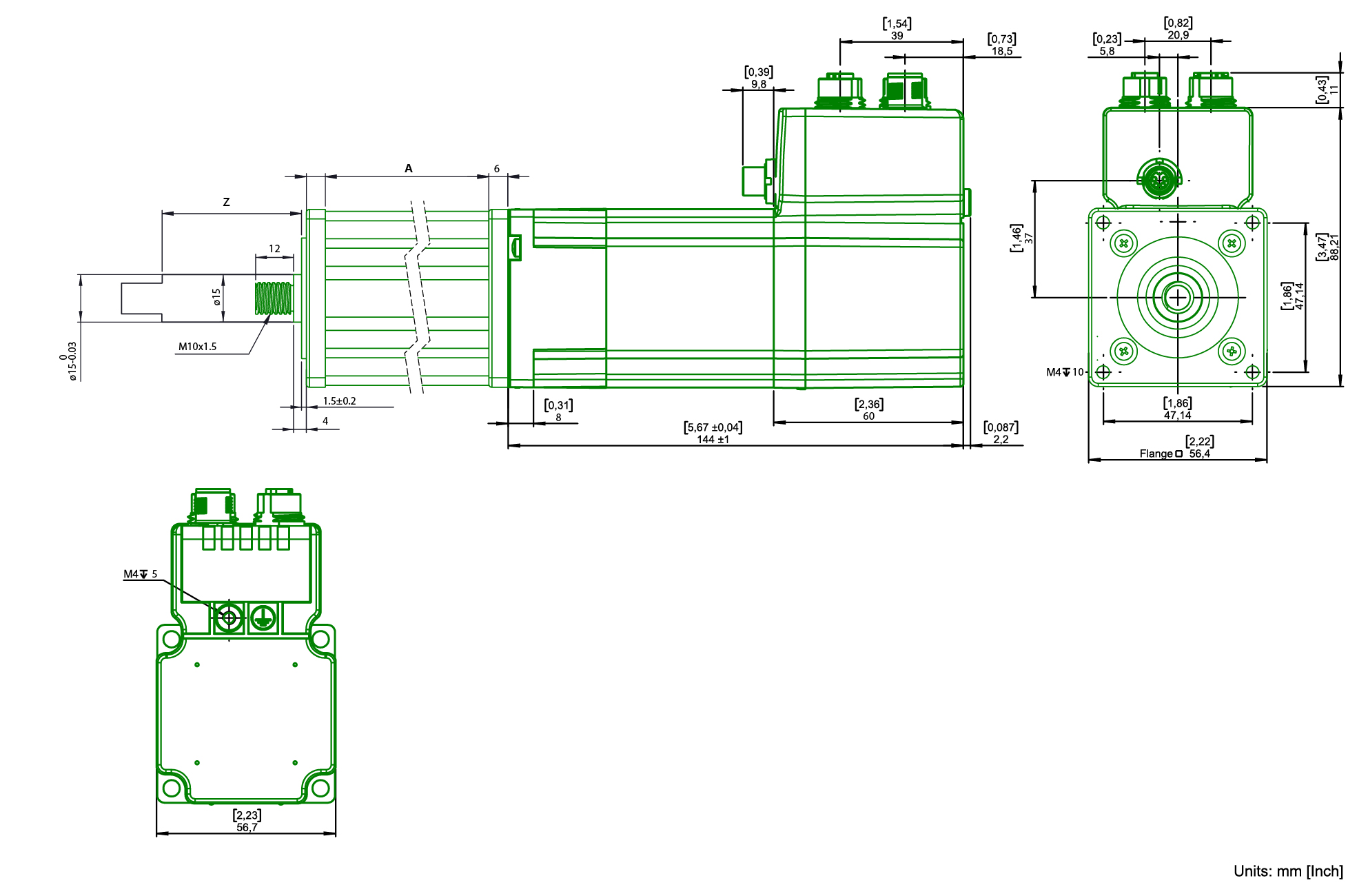

Dimensions |

|

|

|

List of available Captive lead screws

Eg. MIL232SCx-aaHb66z

aa = Q5: PLC IO EC: EtherCat, EL: Powerlink, EI: EtherNet/IP, EP: Profinet, ES: Sercos, EM: MODBUS TCP

b = 2 : Incremental single turn encoder, 4: Absolute multiturn encoder

| Order Code [z] |

Travel Length [mm/inches] [Z] |

Actuator Length [mm/inches*] |

| A |

12.7 / 0.5 |

57.7 / 2.272 |

| B |

19.05 / 0.75 |

64.05 / 2.522 |

| C |

25.4 / 1.0 |

70.4 / 2.772 |

| D |

31.8 / 1.25 |

76.8 / 3.024 |

| E |

38.1 / 1.50 |

83.1 / 3.272 |

| F |

50.8 / 2.0 |

95.8 / 3.772 |

| G |

63.5 / 2.5 |

108.5 / 4.272 |

| L |

127 / 5.0 |

172.0 / 6.772 |

*: Truncated

Force vs. Speed:

For MIL232S - Captive lead screw

| Order code [x] |

Lead [mm/rev]* |

Lead [inches] |

Screw efficiency [%] |

| A |

0.635 |

0.025 |

29.8 |

| D |

1.27 |

0.050 |

36.5 |

| F |

1.6002 |

0.062 |

39.6 |

| H |

2.1082 |

0.083 |

44.3 |

| K |

2.54 |

0.100 |

47.9 |

| L |

3.175 |

0.125 |

52.6 |

| P |

4.2418 |

0.167 |

59.3 |

| R |

5.08 |

0.200 |

63.6 |

| S |

6.35 |

0.250 |

68.7 |

| V |

9.525 |

0.375 |

75.8 |

| W |

9.7536 |

0.384 |

76.1 |

| Y |

12.7 |

0.500 |

78.3 |

| Z |

25.4 |

1.000 |

85.5 |

*: Truncated

Under development! Information is incorrect!

| NEMA17 | NEMA23 | |

| Technical data | ||

| Rod shaft thread hole |

M5 , 15 mm deep | M6 15 mm deep |

| Input shaft |

8 mm. 24 mm deep | 10 mm. 23 mm deep |

| Sleeves |

5 to 8 mm: HSHS17G08M-M05M

6.35 to 8 mm: HSHS17G08M-M06J |

6.35 to 10 mm: |

| Flange size |

45x45 mm | 60x60 mm |

| Input deep groove Ball bearing |

6901 | 6202 |

| Mounting position | Any | Any |

| Protection class | IP42 | IP42 |

| Mechanical data | ||

| Screw Spindle design | Lead scew |

Lead screw |

| Screw | ||

| Max torsion angle of the piston rod degree | ±0.30 | ±0.25 |

| Spindle pitch mm/rev | 1,2,5 | 1,2,5,10 |

| Spindle diameter | 8 mm | 12 mm |

| Max static axial force | 600 N | 1400 N |

| Max feed force | 300 N | 600 N |

| Max speed | 0.5 m/s | 0.5 m/s |

| Max rotational speed | 3000 RPM | 3000 RPM |

| Max acceleration | 6 m/s2 | 6 m/s2 |

| Reversion backlash ball screw | 0.05 mm | 0.05 mm |

| Reversion backlash lead screw | 0.2 mm | 0.2 mm |

| Repetition accuracy ball screw | ±0.02 | ±0.02 |

| Repetition accuracy lead screw | ±0.07 | ±0.07 |

| No load driving torque 200 RPM without rod sealing (IP41) | 0.12 Nm | 0.2 Nm |

| No load driving torque 200 RPM with rod sealing (IP65) | 0.18 Nm | 0.3 Nm |

| Weight | ||

| Basic weight with 0 mm stroke kg* | 1.2 | 2.0 |

| Additional weight per 10 mm stroke kg* | 0.05 | 0.08 |

| Moving load with 0 mm stroke kg* | 0.3 | 0.5 |

| Moving load per 10 mm stroke kg* | 0.01 | 0.02 |

| Mass moment of inertia | ||

| With 0 mm stroke kgcm2* | 0.13 | 0.7 |

| Per meter stroke kgcm2/m* | 0.13 | 0.9 |

| Per kg working load kgcm2* | 0.0023 | 0.03 |

| Environmental condition | ||

| Ambient temperature °C | 0 to 50 | 0 to 50 |

| Storage temerature °C | -25 to 60 | -25 to 60 |

| Protection piston rod | Std. IP41. Optional IP65 | Std. IP41. Optional IP65 |

| Protection cylinder | IP65 | IP65 |

| Relative air humidity | 0-95% | 0-95% |

| Maximum permissible loads on the piston rod | ||

| Fxmax static N | 600 | 1400 |

| Mxmax Nm | 1 | 1 |

| Mymax, Mzmax | 8 | 20 |

| F (L=0 mm stroke) | 100 N | 250 N |

| F (L=150 mm stroke) Value can be higher but depends on duty cycle, speed, acceleration etc. | 40 N | 80 N |

|

DETAILED

|

|

DOWNLOAD

|

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk