CANopen for the ServoStep™

integrated stepper motors

PRESS release: May 2021

Birkerød, Denmark - JVL A/S, one of the world’s leading producers in the field of integrated servo and stepper motors, is announcing an improved implementation of the CANopen protocol for slave operation.

CANopen Key Features

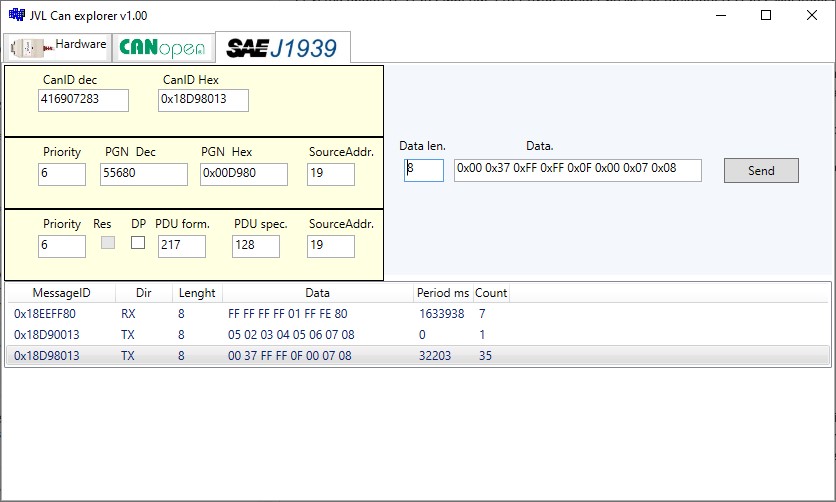

All motor functions are available in CANopen through gateway objects with selectable data rate up to 1 Mbit/s. Monitoring and debugging features with JVL’s MacTalk® software. CANopen over MacTalk® also possible. Easy configuration from PLC through JVL CAN explorer.

- CANopen – DS 301 and DSP 402 support

- CANopen – DSP402 in Profile Position & Velocity mode, Homing (Zero Search) mode and Interpolated Position mode

- Read and write access to all 512 motor registers

- Up to 24 programmable TX PDO and 24 programmable RX PDO

- ≥ 5 kHz asynchronous PDO update with default mapping

- ≤ 2 ms interpolation synchronization

- EDS Electronic data sheet

- TwinCAT 3 compatible: TwinCAT 3 sample project can be downloaded

- CANopen as NC axis in TwinCAT - step by step TwinCAT 3 setup guide

Other CAN bus Features

JVL has developed another smart feature for ServoStep™ motors running CAN bus: the "Slave-follower-mode”.

With this mode you don’t need an external master – you simply use one of the motors as Master and the other motors as Slaves. Up to 8 motors can run synchronized. Contact JVL to learn more about this Master-Slave mode. NB! This mode doesn’t follow the CANopen standard.

With this mode you don’t need an external master – you simply use one of the motors as Master and the other motors as Slaves. Up to 8 motors can run synchronized. Contact JVL to learn more about this Master-Slave mode. NB! This mode doesn’t follow the CANopen standard.

New firmware

|

The MIS motor range MIS17/23/34/43 and Stepper Motor Controller SMC66/85 now have a completely new firmware update including DSP402 where sync, interpolated position mode is supported. JVL now supports master-slave synchronization without external PLC. The new feature will let you quickly set up applications like lifting a load in 4 corners. MacTalk is used to program the master motor. You can connect up to 29 slaves. The master automatically finds the slaves on the bus, and the master automatically. configures them. A primary benefit is the speedy setup time. For easy control, a JVL HMI can be added to the master motor. The new Master-slave feature is supported by all MIS Integrated ServoStep motors with CANopen.

|

|

|||||

- All motor functions available in CANopen through DS301 gateway objects

- Easy configuration and test of SDO and PDO from PC through JVL CANexplorer.

- DSP402 with Profile Position Mode, Velocity Mode, Homing Mode, and Interpolated Position Mode.

- Non CAN standard Master-slave follow motor where up to 30 motors can run synchronized

- TwinCAT 3 compatible

- Synchronized velocity mode

- Synchronized Position mode

- Synchronized homing.

- Slave monitoring

- Speed correction for closed loop motors

- Up to 29 slaves

- Sync interval 10 mS

- Under development sync interval 2 mS with max 8 slaves

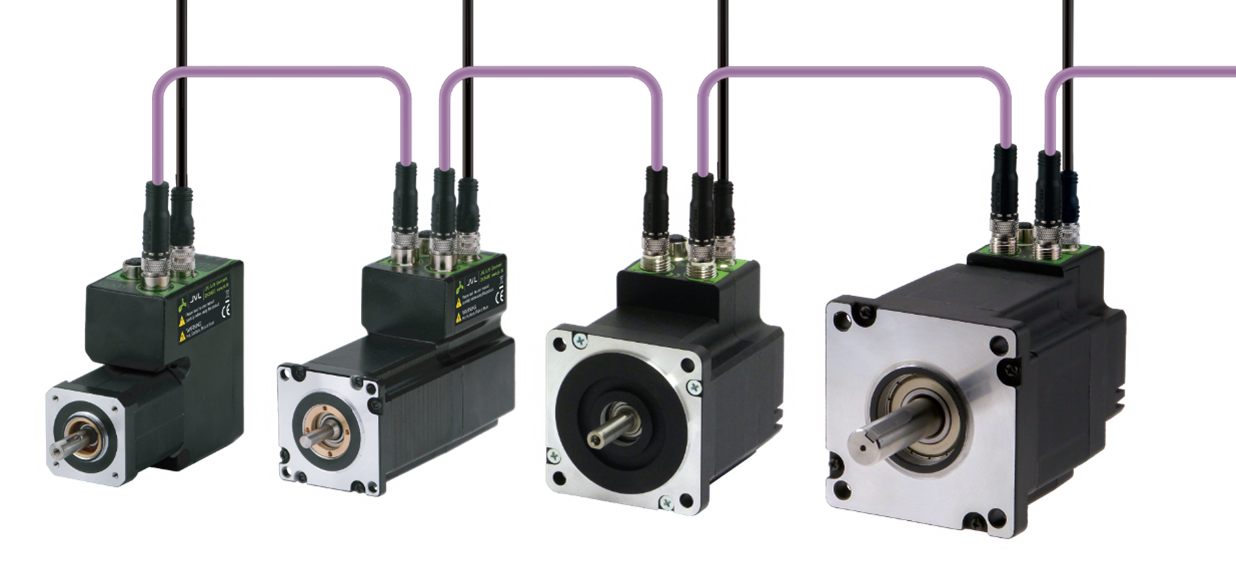

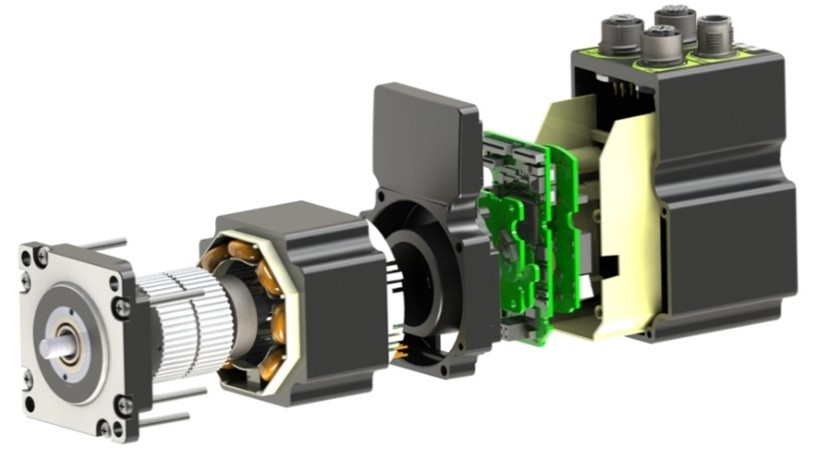

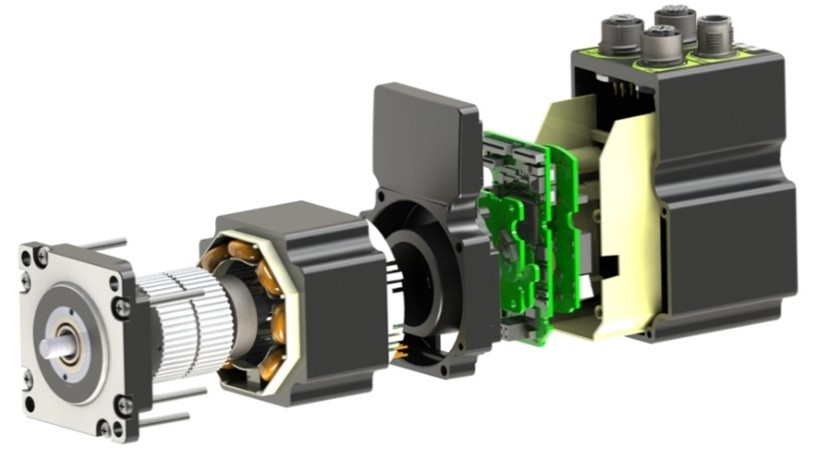

JVL’s integrated stepper motors have everything built-in: high torque motor, incremental or absolute multiturn encoder, driver electronics, controller electronics with ePLC™ and RS485 communications bus. Also included are 8 I/O points which can be individually configured as digital input, digital output or analogue input.

The CANopen circuit include transceiver hardware and two M12 connectors for easy daisy-chaining of cables from motor to motor.

The CANopen circuit include transceiver hardware and two M12 connectors for easy daisy-chaining of cables from motor to motor.

Motor specifications

- Wide size range from NEMA 17 to NEMA 43 with Holding Torques of 0.18 - 25 Nm

- Closed-loop control – no loss of steps or position

- Energy efficient due to Automatic current control

- Built-in ePLC™ with 8 DIO, 24V or 0-5V (12bit) analog input with advanced filtering

- Ultra-high resolution: 409600 step/rev

- Speed-resolution down to ±0.01 RPM

- Change speed or torque or other parameters ”on-the-fly” (while driving)

- Top or rear-end mounted M12 connectors or Option M23 hybrid connector

- Instead of CANopen there are options for all major industrial Ethernet protocols

- Option: Absolute multiturn encoder

- Option: Double shaft and electro-mechanical brake

- Option: STO (safe torque off, SIL3)

CANOpen product page here https://www.jvl.dk/1043/stepper-motor-controllers-canbus

For further information, please contact:

JVL A/S, Bregnerødvej 127, 3460 Birkerød, Denmark.

Tel. +45 4582 4440. E-mail: jvl@jvl.dk. Web:

www.jvl.dk

About JVL - JVL is a world leader within the development and production of efficient and compact integrated servo motors and integrated stepper motors. MAC motor® are a series of integrated brushless servo motors (up to 4500 W and 13.5 kW peak) and ServoStep® are a series of integrated stepper motors (up to 25 Nm). Both the servo motor and stepper motor series include motor, controller, ePLC, encoder and bus system integrated into one compact unit. All industrial Ethernet protocols like Profinet, EtherNet/IP, EtherCAT, Sercos III, ModbusTCP and Powerlink are available.

Options include: absolute multiturn encoders, STO (safe torque off, SIL3) and brakes.

JVL has more than 25 years of motion control experience and are well known for their development and production of highly specialized integrated motors with industrial Ethernet and customized improvements. The close co-operation with customers and representatives result in cost-effective and technical optimized solutions for both basic and advanced motion control applications.

JVL's wide selection of quality products for motion control applications include: Integrated brushless Servo motors, Integrated Stepper motors, AC Servo motor controllers, Motor drivers (DC, AC and Steppers), Brakes, Gearboxes, Hollow Rotary Actuators and HMI touch panels.

Options include: absolute multiturn encoders, STO (safe torque off, SIL3) and brakes.

JVL has more than 25 years of motion control experience and are well known for their development and production of highly specialized integrated motors with industrial Ethernet and customized improvements. The close co-operation with customers and representatives result in cost-effective and technical optimized solutions for both basic and advanced motion control applications.

JVL's wide selection of quality products for motion control applications include: Integrated brushless Servo motors, Integrated Stepper motors, AC Servo motor controllers, Motor drivers (DC, AC and Steppers), Brakes, Gearboxes, Hollow Rotary Actuators and HMI touch panels.

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk