|

Order no. |

Torque

Holding/Running

(Nm)* |

Protec-

tion

(Optional) |

|

|

Stepper Motor NEMA17 42x42mm Flange

|

|

|

0.18/0.18

0.40/0.40

0.78/0.78

|

Standard IP42 (IP65)

|

Integrated w/ SMC66 |

|

Stepper Motor NEMA23 57x57mm Flange

|

|

|

0.97/0.97

1.97/1.97

3.08/3.08 |

Standard IP42 (IP65)

|

Integrated w/ SMC66

|

|

|

|

1.16/1.16

2.53/2.53

|

Standard

IP42 (IP65)

|

Integrated w/ SMC66 |

|

MIS231A

MIS232A

MIS234A |

1.3/1.1

1.8/1.6

3.0/2.9 |

Standard

IP42

(IP65) |

Integrated |

|

Stepper Motor NEMA34 86x86mm Flange

|

MIS340C

MIS341C

MIS342C

MIS343C |

3.0/3.0

6.1/6.1

9.0/7.5

12.0/10.0 |

Standard

IP42

(IP65) |

Integrated |

|

Stepper Motor NEMA43 110x110mm Flange

|

MIS430C

MIS431C

MIS432C |

10.0/10.0

18.7/18.7

25.0/25.0

|

Standard

IP42 |

Integrated |

|

*Values are truncated.

|

Order no. |

Max. Current

(A) |

Protec-

tion

(Optional) |

|

|

Stepper Motor Controller SMC75 Max. 3 Amp

|

| SMC75xxMx |

3 |

Standard

IP42 |

SMC75 with housing |

|

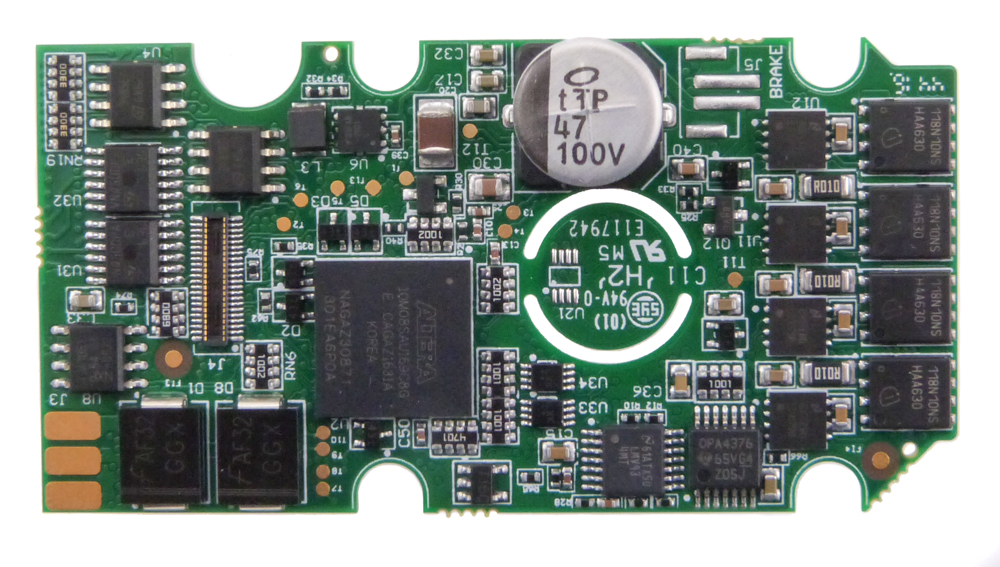

| SMC75xx |

3 |

Open board |

SMC75 with no housing |

|

Stepper Motor Controller SMC66 Max. 6 Amp

|

|

SMC66xx |

6 |

Standard

IP42

(IP65) |

SMC66 with housing |

|

| SMC66xx |

6 |

Open board

|

SMC66 PLC |

|

Stepper Motor Controller SMC85 Max. 9 Amp

|

|

SMC85xxMx |

9 |

Standard

IP42

(IP65) |

SMC85 with housing |

|

| SMC85xx |

9 |

Open board

|

SMC85 PLC |

|

|

|

ServoStep™ - is the complete motion solution. Stepper motors with integrated controller and all necessary components in one unit

The basic idea of the ServoStep™ is to minimize the installation costs but also to make a component that is much better protected against electrical noise which can be a problem when using long cables between controller and motor.

Motor, encoder, drive electronics, control electronics with ePLC™ and optional Ethernet or CANopen are integrated into one compact unit. All major industrial Ethernet protocols like Profinet, EtherNet/IP, EtherCAT, SERCOS, ModbusTCP/UDP and Powerlink are available.

Options include: absolute multiturn encoders, STO (safe torque off, SIL3) and brakes.

Torque range is from 0.18 to 25.0 Nm.

New Innovative Technology

The modern design incorporates closed-loop operation - providing higher torque, faster acceleration, torque control, stall free operation and quieter movements than traditional stepper motor systems.

ServoStep™ has higher efficiency and runs cooler because motor phase currents are regulated up and down according to need. Performance of JVL closed-loop steppers are similar to servo motors, but with higher torque and often without the need of a gearbox, resulting in cost savings.

Design safety factors have always been high for stepper motors to ensure stall-free operation – now with ServoStep™ closed-loop the motors can be operated very close to the limit resulting in even lower costs and more compact designs.

Adapt your motor to your application with different firmware

All ServoStep™ motors have built-in RS485 communications port and programmable ePLC™ with optional CANopen interface. Another option is industrial Ethernet: you can choose between all major Ethernet protocols - Profinet, EtherNet/IP, SERCOS, EtherCAT, Powerlink or Modbus TCP/UDP.

You can even change between the different Ethernet protocols by changing the firmware using the MacTalk® software – and the protocol change is free-of-charge and you can change as many times as you like!

Read more in the ServoStep brochure or click on the pictures for more information.

|