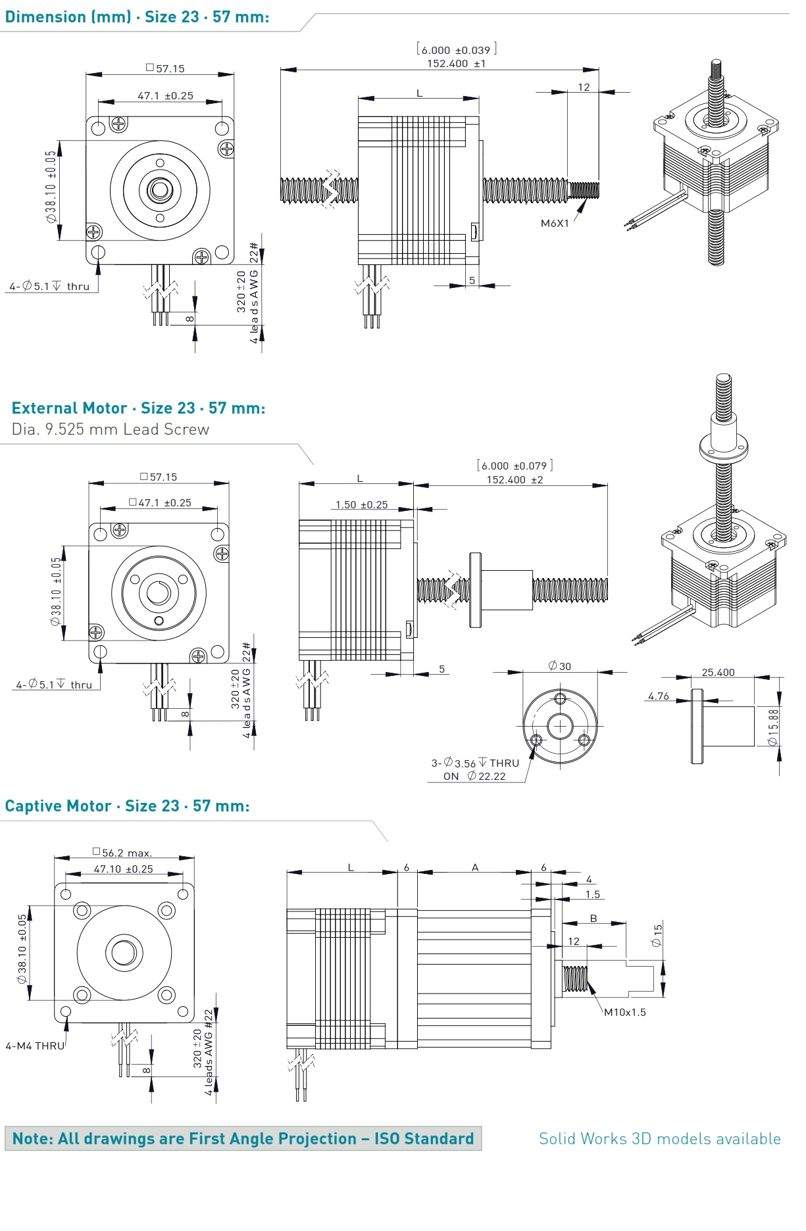

NEMA23 57mm Stepper Motor Linear Actuators

|

|

|

|

|

|

||

|

|||||||

| Motor Type | Voltage [V] |

Current [A] |

Resistance [Ω] |

Inductance [mH] |

Lead Wire No. | Motor Length (L) [mm] (inch) |

Weight |

| MSL231Axy - 4L3AA1.0z | 6.4 | 1.0 | 6.4 | 16.4 | 4 | 47 (1.850) | |

| MSL231Axy - 4L3AA2.0z | 3.2 | 2.0 | 1.6 | 4.1 | 4 | 47 (1.850) | |

| MSL231Axy - 4L3AA3.0z | 2.1 | 3.0 | 0.7 | 1.7 | 4 | 47 (1.850) | |

| MSL232Axy - 4L3AA1.0z | 10.8 | 1.0 | 10.8 | 32.0 | 4 | 66 (2.598) | |

| MSL232Axy - 4L3AA2.5z | 4.2 | 2.5 | 1.7 | 5.2 | 4 | 66 (2.598) | |

| MSL232Bxy - 4L3AA4.0z | 2.4 | 4.0 | 0.65 | 2.0 | 4 | 66 (2.598) |

Notice for external nut versions:

Plastic nut are standard but nut can also be delivered in bronze (material H59) with same size as plastic nut and same price as plastic. Anti-backlash nut in plastic and Teflon coated lead screw are also available for all sizes external nut motors. Optional can rolled ball screw be delivered in selected pitch e.g. 1mm/rev or 5mm/rev. Please ask JVL for more information.

Plastic nut are standard but nut can also be delivered in bronze (material H59) with same size as plastic nut and same price as plastic. Anti-backlash nut in plastic and Teflon coated lead screw are also available for all sizes external nut motors. Optional can rolled ball screw be delivered in selected pitch e.g. 1mm/rev or 5mm/rev. Please ask JVL for more information.

| Lead Code [y] | Travel Per Rev.* [mm] (inch) |

Force [N] (lbs.) |

Force (double stack) [N] (lbs.) |

Screw Dia. [mm] (inch) |

| 3 | 2 (0.079) | 8 (0.315) | ||

| 4 | 4 (0.158) | 8 (0.315) | ||

| 6 | 8 (0.315) | 8 (0.315) | ||

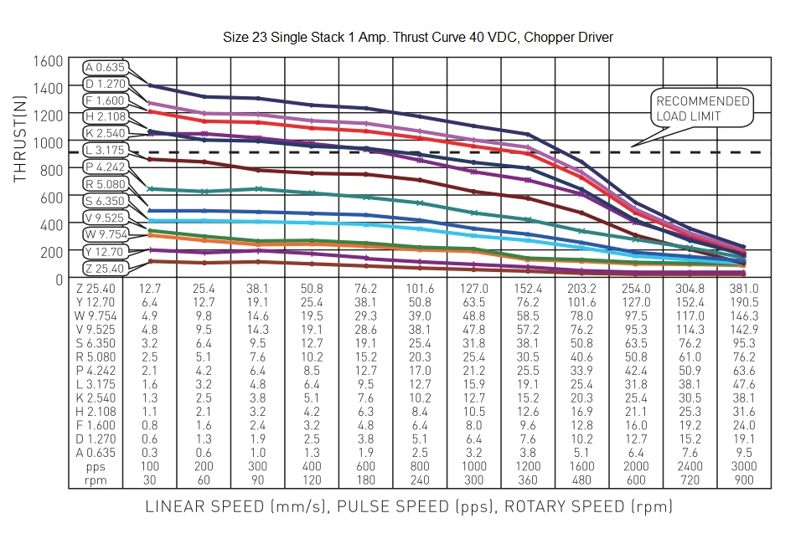

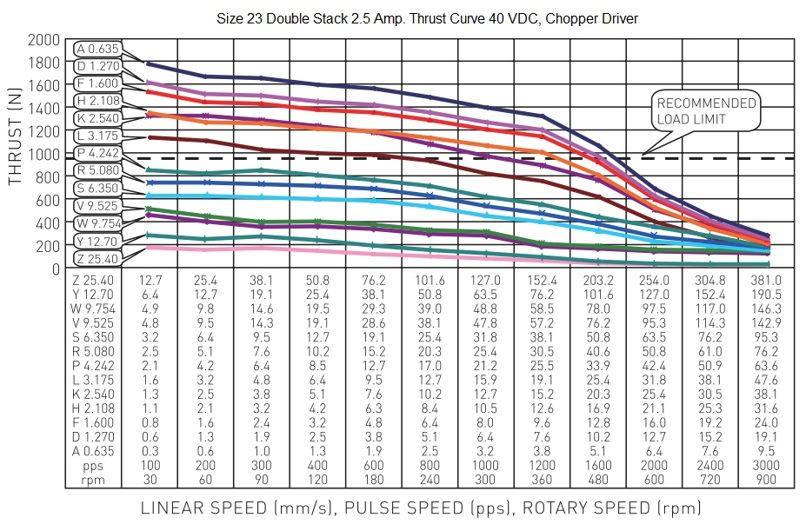

| A | 0.635 (0.025) | 1400 (314.7) | 1750 (393.4) | 9.525 (0.375) |

| D | 1.27 (0.05) | 1280 (287.8) | 1600 (359.7) | 9.525 (0.375) |

| F | 1.6002 (0.063) | 1200 (269.8) | 1500 (337.2) | 9.525 (0.375) |

| H | 2.1082 (0.083) | 1050 (236) | 1300 (292.3) | 9.525 (0.375) |

| K | 2.54 (0.1) | 1050 (236) | 1300 (292.3) | 9.525 (0.375) |

| L | 3.175 (0.125) | 880 (197.8) | 1100 (247.3) | 9.525 (0.375) |

| P | 4.2418 (0.167) | 650 (146.1) | 850 (191.1) | 9.525 (0.375) |

| R | 5.08 (0.2) | 500 (112.4) | 750 (168.6) | 9.525 (0.375) |

| S | 6.35 (0.25) | 400 (89.9) | 610 (137.1) | 9.525 (0.375) |

| V | 9.525 (0.375) | 350 (78.7) | 500 (112.4) | 9.525 (0.375) |

| W | 9.7536 (0.384) | 300 (67.4) | 450 (101.2) | 9.525 (0.375) |

| Y | 12.7 (0.5) | 200 (45) | 300 (67.4) | 9.525 (0.375) |

| Z | 25.4 (1) | 100 (22.5) | 190 (42.7) | 9.525 (0.375) |

Note: All above screws can be used on external drive style.

Non captive style can only select dia. 9.525 mm screws.

Non captive style can only select dia. 9.525 mm screws.

*Based on 200 step/rev motor. Divide with 200 to get travel per step. If JVL driver/controller with 1600step/rev

are used divide with 1600 to get travel/step (SMD73,SMD74,SMC75).

are used divide with 1600 to get travel/step (SMD73,SMD74,SMC75).

Screw dia 9.525 weight 0,455 g/mm.

Appropriate driver or controller for NEMA23 to NEMA34

| Size 23 | Captive (C), External nut (E), Ballscrew (B) | Non captive (N) |

| Axial load | Max 800N * | |

| Axial play (Endplay) | Max 0.1 mm * | |

| Radial load | 0 N ** | 0 N |

| Radial play | 0 mm | 0 mm |

| Recommend load limit | Max 1750N | Max 1750N |

* We don´t use wave washer and we applied pre-load to the bearings. So the axial play is very small, it comes from the mechanical deform when there is axial load, it should be less than 0.1mm.

** For the motor with screw shaft, there should be no radial load on the screw, otherwise the shaft will be bend and affect the linear accuracy.

Normally the lifetime will typical be as following but will depends on load, force, acceleration, speed, temperature and many other factors.

| Nut Type | External Plastic | External Bronze | External Anti-backlash | Non-captive | Ball Screw |

| Lifetime (in cycles) |

3.000.000 | 200.000 | 3.000.000 | 3.000.000 | 10.000.000 |

Standard motors are Class B rated for maximum temperature of 130 °C. Standard protection grade IP42 and higher on request. Motor can also be delivered as a 6 wire unipolar with 30% less force. Other travel per stepm, special nut and mechanical shaft dimensions/length can also be delivered. Weight and inertia depend upon shaft length. All measures in mm. All electrical tolerances 10%.

| Stroke | Dimension B [mm] (inch) Stroke |

Dimension A [mm] (inch) |

Dimension L [mm] (inch) Single Stack |

Dimension L [mm] (inch) Double Stack |

| A | 12.7 (0.5) |

57.7 (2.271) |

89 (3.503) |

108 (4.251) |

| B |

19.05 (0.75) |

64.05 (2.521) |

89 (3.503) | 108 (4.251) |

| C | 25.4 (1.0) |

70.4 (2.771) |

89 (3.503) | 108 (4.251) |

| D | 31.8 (1.25) |

76.8 (3.023) |

89 (3.503) | 108 (4.251) |

| E | 38.1 (1.5) |

83.1 (3.271) |

89 (3.503) | 108 (4.251) |

| F | 50.8 (2.0) |

95.8 (3.771) |

89 (3.503) | 108 (4.251) |

| G | 63.5 (2.5) |

108.5 (4.271) |

89 (3.503) |

108 (4.251) |

| L | 127 (5.0) |

172 (6.771) |

89 (3.503) | 108 (4.251) |

|

DETAILED

|

|

|

|

DOWNLOAD

|

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk