Danfoss assembling Pressostats and Thermostats using JVL Equipment

|

TurnMaster Turntable, JVL Servo Controllers and Yaskawa Motors used in Assembly Units

Danfoss´s Automatic Controls Division manufactures the world-renowned RT Thermostats and Pressostats, which recently celebrated their 60th year as one of the products that Danfoss has produced almost without change. Production methods themselves have however changed since 1937 and recently Danfoss has developed and constructed new assembly units for thermostats and pressostats in order to rationalise and improve production. The mechanical components used in the assembly units are produced at Danfoss's own machine shop.

Assembly of the Thermostat and Pressostat adjustment spindle is carried out using JVL's TurnMaster Turntable, a Yaskawa AC servo-motor and a Harmonic Drive play-free gear. This process is controlled by a JVL AMC11B AC Servo Controller operating in register mode. Five balls and a disc are mounted in the spindle, which is then flanged at the end so that the disc and balls are fixed as a small ball bearing. The turntable rotates at 30° intervals. Every 60°, balls are inserted, a spindle is positioned over the assembly and

Turntable for assembling spindles.

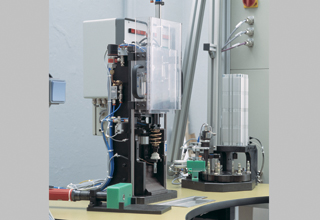

Set-up for assembling the spindle, spring, end-plate in the pressostat/thermostat housing.  The complete assembly set-up. |

|

the end is flanged. Offset 30°, an inductive sensor is used every 60° to check that an O-ring has been positioned and that the balls and disc are in place.

The completed spindle is then assembled in a plastic housing with a spring and end-plate. Here the spindle is screwed in to the required depth by another Yaskawa AC servo motor that is also controlled by an AC Servo Controller AMC11B. The motor is velocity controlled depending on the depth required, which is controlled pneumatically. All other motion in the assembly units is controlled by Festo pneumatics. Overall control of both assembly units is done by a Hitachi PLC via the field bus system Interbus, to which Festo´s pneumatics are also connected. Regarding the choice of JVL´s turntable for this application, Danfoss's development team emphasises the turntables' great stability, self-locking and the facility to freely select the resolution. For our part, JVL has been very pleased that we could contribute to the solution of the assembly task.  The finished spindle and the components used in assembly.

Assembly of the units in housing.

JVL AMC11B AC Servo Controllers mounted in the control cabinet. |

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk