MAC400 - JVL's latest development in integrated servo motors.

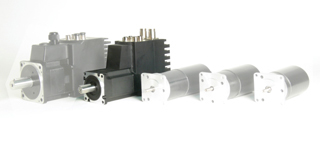

Throughout the past 10 years, JVL has developed servo motors with integrated controllers. Already back in 2000, JVL launched the first MAC motor series with rated torques of 0.1 to 0.5 Nm. This product range has demonstrated quality on a par with, if not better than, traditional servo systems.

Initially there was some scepticism among customers about combining the controller and motor in a single housing and mounting this directly on machines. But experience has shown that through proper selection of components that are suited to the harsh requirements of machine environments, users have gained significant benefits: from design, purchase and commissioning to final operation of machinery.

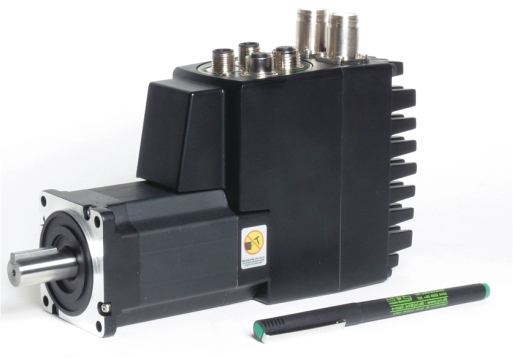

JVL has continued development of integrated servo motors, and with the launch of the MAC800 we combined yet another component stage by adding the power supply to the motor, so that supplies of 230/115 VAC could be directly applied to the unit. The led however to more stringent design requirements since JVL required that the MAC800 could deliver a peak torque 3 times the nominal rated torque and that the motor complied with standards for UL-approved components, where special temperature requirements and distance between PCBs and the housing are decisive.

Today, JVL is the only supplier that offers a UL-approved integrated servo motor.

MAC400, pushing the boundaries

The MAC800 was a huge step forward in the development of integrated servo motors. Customers from many segments were now aware of the advantages offered by this technology.

At the same time, our customers were met by requests from end-users for machines that were smaller and more compact and for complete solutions that were less expensive. With these factors in mind, JVL set about increasing capacity in the form of additional inputs and outputs, ‘fast input’, faster updating times, increased interfaces for using bus protocols, and we developed a new kernel for a new MAC400, 400W motor.

JVL already knew that the market for 400W servo motors is where the greatest competition lies and therefore the following requirements were to be met:

· Reduction in the number of PCBs compared to MAC800

· Upgrade of processor power

· Inclusion of 230/115 VAC power supply as in the MAC800

· Handling absolute multi-turn encoder

· Extra inputs and outputs compared with the MAC800

· Fulfil the requirements of UL-approved products

· General focus on cost in the selection of components and production processes.

On this basis, JVL presented a prototype at the SPS fair in Nuremberg in 2008 and initial feedback from the first tests in customers’ applications demonstrated that all of the above requirements were fulfilled.

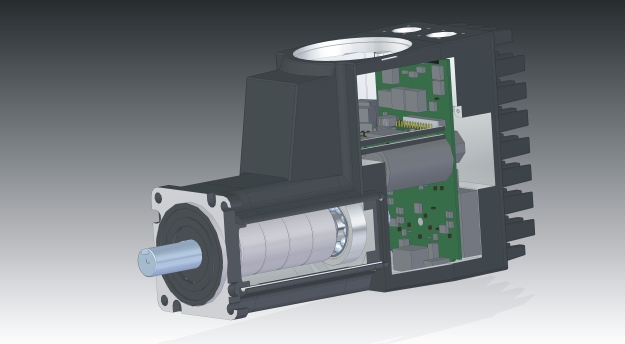

JVL can now present a product that is unique in that the MAC400 only has 2 PCBs, compared to the 5 of the MAC800. For compliance with UL requirements, this has only been possible through the use of completely new technology by embedding the entire power supply to ensure UL temperature and spacing requirements.

Utilising a new processor, which will become the common platform for all future MAC motors, the requirements for improved processor speed, handling ‘fast input’ and absolute multi-turn encoders have been fulfilled. In addition, there is now the facility for handling nanoPLC functionality directly via the processor, and not as currently the case with other motors which require a MAC00-Rx expansion module. Furthermore it is also possible to use an external encoder signal either as a master or slave at the same time as executing bus communications.

It was clear from the start of development of the MAC400 and the new platform, that JVL wanted a solution which would support the new Ethernet-based protocols such as EtherCat, PowerLink and ProfiNet, to mention but a few. The only change required to use the MAC400 in a network is to download the correct software to support the desired protocol.

The MAC400 is JVL’s response to how latest technology can be used to give the user a solution which provides:

· Savings by in-design, since only a single component is incorporated

· Savings in procurement and fewer component orders.

· Savings in cabinet space, which in some cases can be omitted entirely

· Savings in installation and reduced cabling

· Savings in commissioning: the product is already burn-in tested, both the motor and controller together

· A complete servo solution with user-friendly software for commissioning and adjustment

· One of the market’s most compact products, without loss of performance.

For further details of the MAC400 or other JVL products, contact us on +45 4582 4440 or via jvl@jvl.dk

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk