Valve test Machines use JVL MAC Motors

|

TWINS SRL in Italy uses MAC141-A1/MAC00-B1 for valve control.

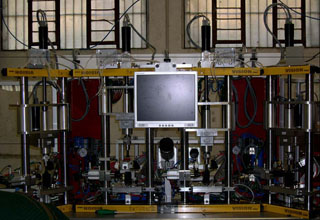

Twins srl is a testing machines manufacturer and a valve-assembly machine manufacturer. This company has been working together with JVL representative in Italy, SERVOTECNICA, for many years. They are shifting from step motor technology to a brushless technology in their test equipment, principally on full-automatic lines, but increasingly on the semi-automatic lines. The first application we have carried out together with Twins is on semi-automatic equipment, because also on this type of machine the number of the automated axes is increasing, and this causes space problems inside the control cabinet. The machine in the first picture is a valve testing machine. On the machine base there are four independent stations and each station performs the same job: - After the operator has mounted the valve, the Z-axis releases the valve security system, and the C-axis turns the valve tap in two directions. - A pressure measurement system checks if the valve works properly in the totally open and totally closed positions. - The system is also able to check if the security push-and-release of the tap works properly. In this application the customer uses MS-Dos software, which means that there is no way to use high-speed bus communication systems such as Canbus or Profibus, because the hardware manufacturers do not develop MS-Dos drivers for their electronic cards. We therefore opted for the MAC00-B1 serial communication module, because of the high number of motors connected to the PC board, they decided to use a daisy-chain connection using a standard RS232 serial port. Depending on the application there are two motors on every station; one is connected to a screw drive mechanism, and the other to a pulley drive. The Z-axis has to be able to stop in a precise position, in order to be sure not to engage the security release valve system, and to check its proper functioning.

Once the Z-axis is in position, the C-axis driven by the second motor turns the valve tap from the totally open position to totally closed, checking that there is no air transfer through the valve. After this first job, the C-axis motor turns the valve tap to the closed position a second time, the Z-axis engages the security push-and-release system (in practice by pushing the shaft of the tap), and the C-axis performs another movement from the totally closed to the totally open condition. During this movement, the pressure transducer connected to the PC software draws a curve of the air reach of the valve. Once this job is completed, the C-axis again turns the tap to the totally closed condition and the test is complete. The entire test sequence is totally automatic, which means that the operator can load another station and unmount the tested valve. |

|

Valve testing machine

Detail of valve testing machine

The small electric cabinet located on the top of the machine.

The last picture provides a view of the small electric cabinet located on the top of the machine.

It’s clear how many problems are solved with the MAC141 motors by decentralizing the electronics directly on each individual motor. It is also very helpful if the manufacturer is required to add new additional stations to the same base at a later date (often requested by their customers), as they do not have to consider the number of drives or where and how to locate the drivers in the cabinet. More information about:

|

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk