Computer-controlled Camera-robot uses JVL Step- and Servo motor Controllers

SFX, Motion Control Animation achieved using a specially constructed Danish camera-robotFor many years, the Danish company CMC has built up extensive know-how and expertise from Allan O. Lückow's numerous trips to the USA and UK in connection with the recording of animated films using specially constructed motor-controlled camera set-ups. The principle of this film technique, which is widely used for puppet work and advertising films, involves using a computer to control the position of the camera in relation to the subject and taking individual shots in each position. In this way, the impression that the film has been recorded in real time is created. The camera is mounted on a robot and motors are used to control all movement. The motors themselves are controlled by drivers via a computer running special software. In addition to moving the camera between each frame shot, the computer is used to control lighting, and objects on Model Movers can be animated, controlled by motors and drivers via the same computer. Throughout the years, JVL A/S has contributed to the development of such camera-robots at CMC with our expertise in the field of motor control and by supplying step motors, gears and drivers. CMC´s latest camera-robot is controlled by a total of 10 step motors with associated JVL Drivers. A large AC servo motor with associated Yaskawa driver (also supplied by JVL) ensures the robot's forward and reverse movement on rails. The 10 step motors control: 1) Dolly forward/back 2) Camera-arm rotation 3) Camera-arm Up - Down 4) Camera Pan, Roll: vertically, rotation, horizontally 5) Zoom and "Fixed Nodal Point", focusing 6) Camera motor 7) Various "Model movers" which move objects The drivers are controlled by a powerful PC using step and directional signals. The software used is RTMC 48 (Real Time Motion Control) from Kuper Controls, which can control up to 48 motors in addition to on/off functions. The entire time sequencing of such film recording can for example be controlled by an SMPTE time-code which ensures complete synchronisation of audio, picture and video signals. The camera itself is a somewhat exclusive Mitchell Fries camera, an older Mitchell camera that has been found to be particularly well-suited for Motion Control Animation and has been modified for this special application by Fries Engineering in Hollywood, USA.

In addition to executing a pre-programmed motion and lighting sequence, the computer can also register a manually performed motion sequence. This is achieved by equipping all the relevant step motors with an encoder that transmits accurate positioning data to the computer when the camera is moved manually. Once the sequence has been registered, it can be repeated accurately for subsequent filming. |

|

Control console with computer and step motor drivers

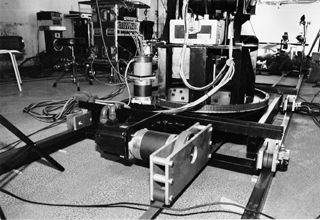

The camera robot in a studio between sequences for the 1997 LEGO campaign

Allan O. Lückow emphasizes that step motors are currently superior to servo motors for this type of filming owing to their great repetition accuracy in the time domain. The position of the camera must be extremely accurate at precisely the instant the shot is taken, even though this is done at various speeds. In addition, it is of course important that the camera doesn't shake during filming and much effort has been used to remove undesirable resonances to ensure that the construction is adequately stiff but mechanically damped. The use of ministep drivers employing a large number of steps per revolution has also helped to avoid resonance problems.

Toothed-belt, gear and chain drive transmissions are used depending on the individual functions, and very high-quality bearings are used. This application of step motors and controllers supplied by JVL is yet another good illustration of the many varied applications where great demands are made on accuracy. Allan O. Lückow points out that he chose JVL as a supplier partly because of the excellent technical support he could obtain throughout the entire development process.

More information about:

|

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk