Mounting methods and advantages for MISmotor with hollow shaft and large 7100N ball bearing

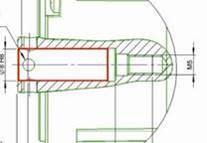

| Mounting methods | Drawing | Advantage | Disadvantage |

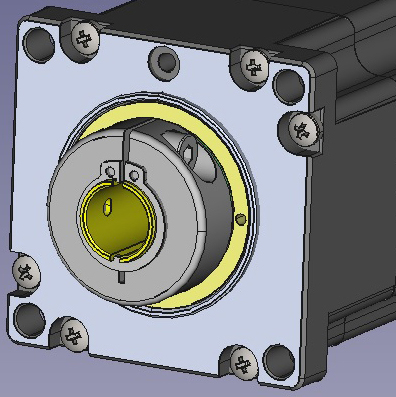

| Clamp |  |

Easy installation. Zero backlash. Can be combined with central axial M5 set screw for higher axial load. Clamp can be removed and pin hole used with Ø3 DIN/EN/ISO 8752 spring pin alone. Clamp and pin in combination for higher torque (length of pin must be adapted to fit inside clamp) . |

If high load spindle/shaft may "slip out” or rotate in motor shaft when clamp is used alone. Clamp must be properly torqued. |

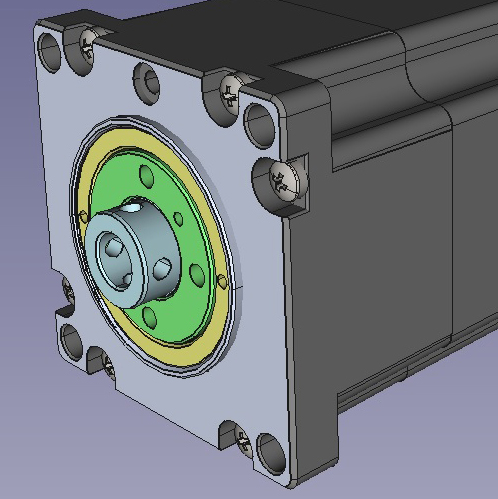

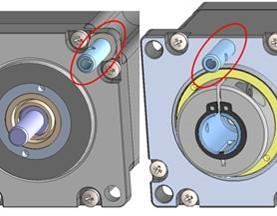

| Bel Pin |  |

High axial load. High Torque Zero backlash. Use high quality Ø3 DIN/EN/ISO 8752 spring pin. Can be combined with radial set screws (shaft should have recess for easier disassembly). |

Hole in ball screw/spindle must be made precisely. It may be difficult to machine hole in hardened ball screw. |

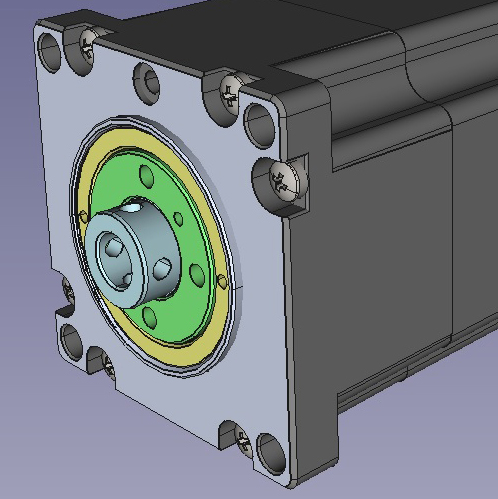

| Radial set screws (2 pcs) |

|

Can be used for D shaft or spindle with indentations or holes for set screw. Can be combined with central axial M5 set screw for higher axial load. |

Not strong mechanical solution in high load long time operation when used alone. |

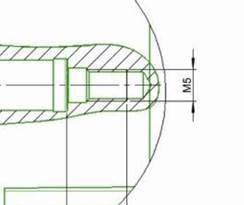

| Axial M5 set screw in shaft hole |  |

Can be used in combination with clamp or radial set screws for even better mechanical connection and higher axial load. It is optional to use the set screw mounting. Ball screw/spindle can either have male M5 tread or female M5 tread in combination with M5 set screw. |

If may be difficult to ad threaded hole to hardened ball screw. |

| Glue |

|

Low cost mounting and easy. |

Demand proper cleaning of internal and external surfaces and use of proper clue. JVL recommend Loctite. Not easy do disassembly. |

| Shaft |  |

Good for coupling, gear, sprocket and belt applications. Keyway and M4 center hole for secure mechanical connection. |

Requires more space than "hollow shaft” solutions. |

| Turn table |

|

4 pcs. M4 hole in inner lock nut for attaching custom made turntable or mechanical equipment. Can be combined with radial set screw from custom part against shaft for increased insurance against lock nut coming loose. |

|

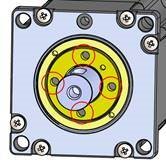

| Torque support pin |

|

Ø6 or Ø10 torque pin can be fitted with M4 screw through corner hole (~33,3mm from center) or with M4 set screw into thread 24 mm above shaft center, available on double ball bearing types. Oblong hole w. width 0,05 to 0,15 mm larger than pin diameter must be made in machine frame. |

Should be used when motor is fitted to shaft/spindle that is "self-supported” by two bearings. |

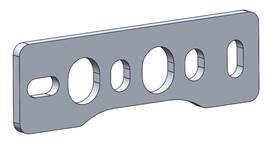

| Torque support Bracket |

|

To be fitted to machine frame. Eliminates need for precise machining of hole for torque pin on machine. Required drilling can be made on site with handheld drill. Matches center or corner fitting of Ø6 and Ø10 torque support pins. |

Useful when fitting motor with torque support to existing machinery. |

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk