2019-11-15

Motors of the Future

Integrated drive technology saves space, cost and is future-proof. It is ready for Industry 4.0 and IIoT

By Palle Sorensen

The Danish company JVL started operation in 1986. The basis for the early success was the use of the latest technologies, which the two company owners skillfully used in their products. Initially, the development and marketing focused on modern and compact driver stages for stepper motors, which found excellent acceptance in the market and the young company grew steadily. By acquiring a Danish competitor, the product portfolio expanded to include AC and DC servo drivers, and the company saw continued growth. The year 2001 would later prove to be a turning point: this was the year when the founders Bo Valeur Jessen and Mads Vernon Jørgensen conceived the idea of combining the brushless AC servo motor and all necessary electronics into one unit. From being a new minor addition to the product palette, slowly but steadily it would grow to become the main product line of the company.

Key Features

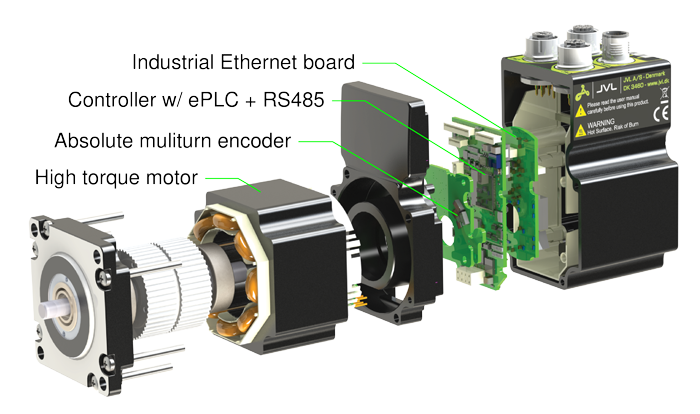

What is the definition of an integrated motor? An integrated motor combines the following components into one unit: servo or stepper motor, encoder, drive electronics, control electronics and an easily programmed embedded PLC (ePLC). An integrated motor can operate as stand-alone unit, utilizing the ePLC, or a master PLC or PC can control it. Options of the control electronics include industrial Ethernet and field busses.

Fig. 1. Exploded view of an integrated motor.

Servo vs Stepper motors

Servo motors offer the highest power-to-size ratio and are the most dynamic motors, and if the average speed is high they also have the edge. Stepper motors offer the highest torque-to-size ratio and are cheaper than servos; in addition they don’t have any jitter when standing still, clearly an advantage in precise measurements.

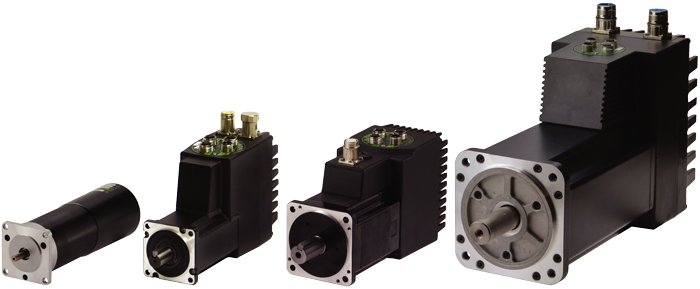

Fig. 2. The family of integrated servo motors, MAC motor®, 50 W to 4.5 kW

JVL’s integrated steppers, ServoStep™, even without extra options, offers some very strong features like closed-loop operation, current control, torque control, ultra-high resolution of 409600 step/revolution resulting in unsurpassed smoothness and silent running plus a wide speed range from 0-3000 RPM with an extreme resolution of just 0.01 RPM.

Fig. 3. The family of integrated stepper motors, ServoStep™, 0.37 Nm to 25 Nm

Popular options include: Absolute multiturn encoders, CANopen, double shaft, hollow shaft, electromechanical brakes (front or rear mounted), special customized connectors and STO Safe Torque Off (TÜV approved). Even wireless options exist: Bluetooth, Zigbee and WLAN – ideal for shuttles, AGVs and other battery supplied applications.

Absolute multiturn encoders are based on the newest technology which eliminates the use of backup batteries: instead a harvesting energy principle is used. In short these encoders will maintain correct position without any time limits and are maintenance-free.

Absolute multiturn encoders are based on the newest technology which eliminates the use of backup batteries: instead a harvesting energy principle is used. In short these encoders will maintain correct position without any time limits and are maintenance-free.

Ready for Industry 4.0 and IIoT (Industrial IoT)

All integrated motors can be delivered with industrial Ethernet onboard. You can choose among all major protocols: Profinet, EtherNet/IP, EtherCAT, Sercos, Powerlink and ModbusTCP/UDP. Cabling is a hassle? Using the onboard Ethernet-switch, you can daisy-chain cables from one motor to the next. Quite uniquely on the market, users can even change Ethernet protocol by updating the firmware using the MacTalk® software – even better it is free-of-charge.

Since JVL supports explicit and cyclic messages, the company’s motors can be used with almost all PLCs and motion controllers.

Since JVL supports explicit and cyclic messages, the company’s motors can be used with almost all PLCs and motion controllers.

Advantages of Integrated Motors

Integrated motors have many advantages and the example below shows how a real-life application gained tremendous benefits by using integrated motors.

Customer requirements to machines and applications are that they must be smaller and smaller, yet include increasingly more functionality. In addition, the motor must use as little energy as possible.

The solution to this is integrated motors. Integrated motors are the motors of the future, since customers need only pay for what they require – and additionally save space in control cabinets and reduce the number of cables and components. Moreover, noise problems from motor cables are eliminated as any noise is confined within the motor.

Customer requirements to machines and applications are that they must be smaller and smaller, yet include increasingly more functionality. In addition, the motor must use as little energy as possible.

The solution to this is integrated motors. Integrated motors are the motors of the future, since customers need only pay for what they require – and additionally save space in control cabinets and reduce the number of cables and components. Moreover, noise problems from motor cables are eliminated as any noise is confined within the motor.

• Save Space

By integrating the motor, controller, power supply and Ethernet interface bus in a single unit, there is no longer a need to mount motor drivers and EMC filters in a control cabinet. Space savings are a minimum of 75% compared with conventional systems.

• Eliminate Noise Problems

Since motor, encoder and electronics are mounted as close together as technically possible inside a metal housing, most noise problems are eliminated. There are no encoder cables to pick-up noise from the environment and there are no high-current motor cables which can induce disturbances in nearby signal cables.

• Save Energy

Integrated motors are specifically developed with the aim of minimizing heat generation by maximizing the efficiency. Highly efficient components and switching technology are used to avoid the motor from over-heating.

Both the motor and the power circuitry generate heat, so each Watt that is eliminated makes the motor correspondingly cooler.

Moreover most JVL motors are UL-approved – and UL certification puts very stringent demands on internal and external temperatures. The standby consumption of integrated motors is typically 50% lower than that of corresponding systems with discrete motors and drivers.

A beneficial side effect of using integrated motors is that heat generation in the control cabinet is reduced significantly so airconditioning and cooling fans are often completely unnecessary.

Both the motor and the power circuitry generate heat, so each Watt that is eliminated makes the motor correspondingly cooler.

Moreover most JVL motors are UL-approved – and UL certification puts very stringent demands on internal and external temperatures. The standby consumption of integrated motors is typically 50% lower than that of corresponding systems with discrete motors and drivers.

A beneficial side effect of using integrated motors is that heat generation in the control cabinet is reduced significantly so airconditioning and cooling fans are often completely unnecessary.

• Adapt to your needs

MAC motor®’s modular construction makes it easy to adapt the motor to the machine construction – now and in the future. If a factory wants to upgrade their installation from e.g. Profibus to Profinet, they only need to exchange the control module in the motor. With interchangeable modules it is easy to switch from one module to another.

When Ethernet modules are used, using the same hardware it will be possible to switch between EtherCAT, Ethernet/IP, Powerlink, and SERCOS. This means that customer outlay is minimized since a module can be adapted to communicate with all common PLCs throughout the world.

MAC motor®’s modular construction makes it easy to adapt the motor to the machine construction – now and in the future. If a factory wants to upgrade their installation from e.g. Profibus to Profinet, they only need to exchange the control module in the motor. With interchangeable modules it is easy to switch from one module to another.

When Ethernet modules are used, using the same hardware it will be possible to switch between EtherCAT, Ethernet/IP, Powerlink, and SERCOS. This means that customer outlay is minimized since a module can be adapted to communicate with all common PLCs throughout the world.

• Reduce Installation Costs

The elimination of expensive shielded encoder and motor cables and the substantial reduction in control cabinet space both contribute to huge installation savings. Installation costs are reduced by up to 65%.

Furthermore all Ethernet and fieldbus options have a built-in switch which further reduce costs by enabling easy daisy-chaining of cables from motor to motor.

The elimination of expensive shielded encoder and motor cables and the substantial reduction in control cabinet space both contribute to huge installation savings. Installation costs are reduced by up to 65%.

Furthermore all Ethernet and fieldbus options have a built-in switch which further reduce costs by enabling easy daisy-chaining of cables from motor to motor.

BEFORE

68 Power + 68 Encoder cables. Twi full size cabinets w/cooling

AFTER

MAC: one supply cable + Ethernet daisy chain + No cabinet space

Fig. 4. "After” and "before” using integrated servo motors, MAC motor®.

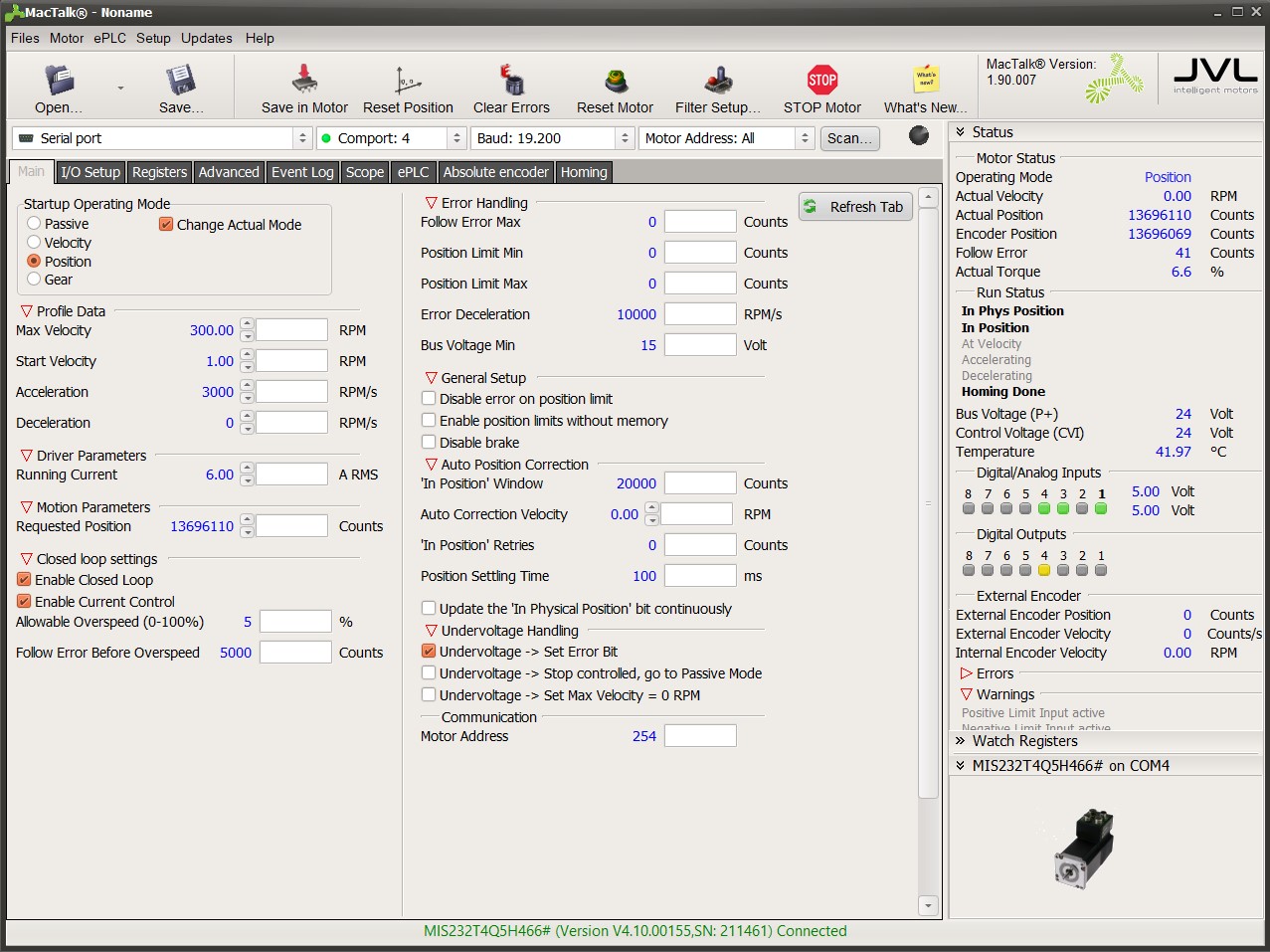

Software Support

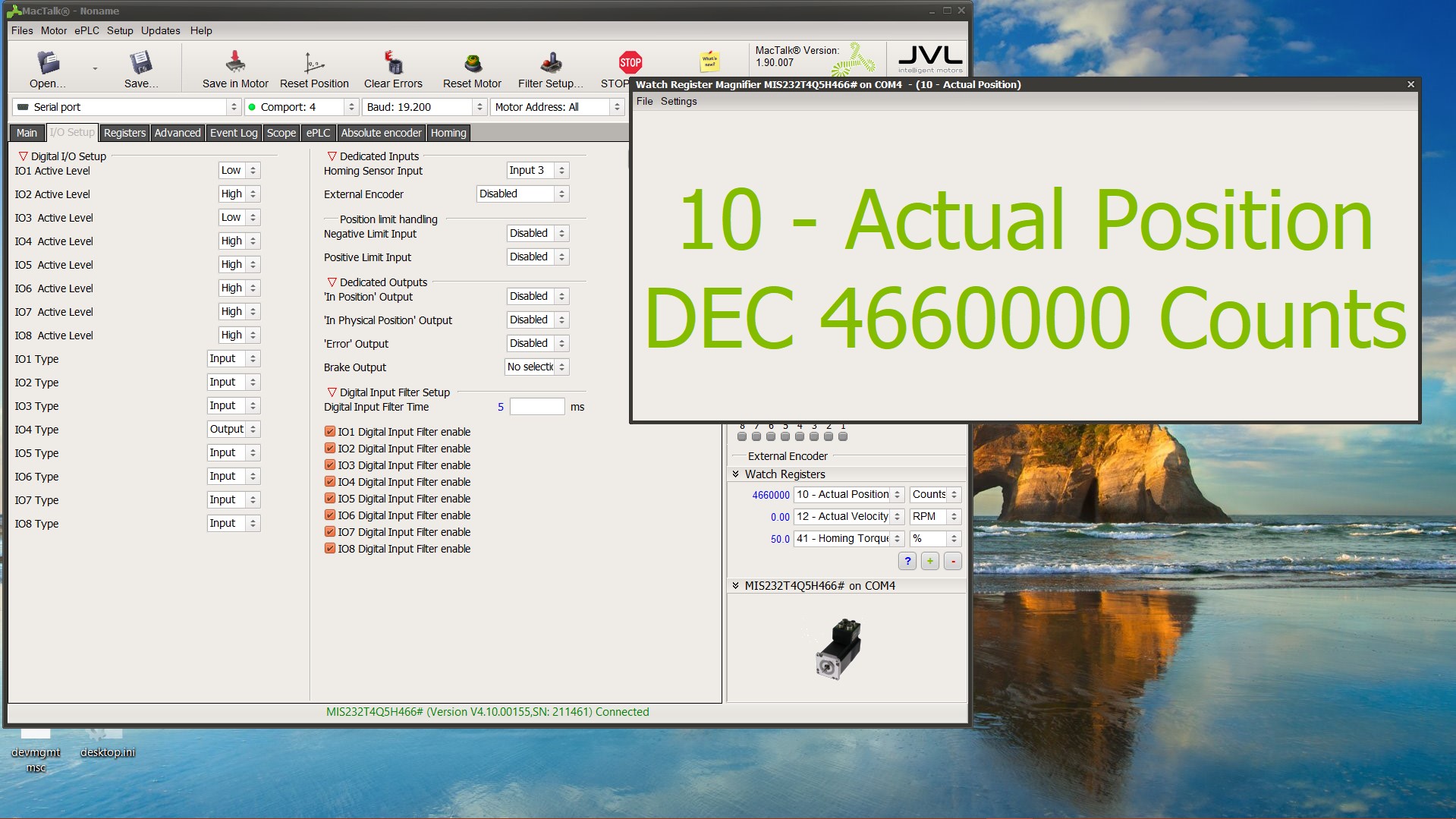

To support the whole range of integrated motors, servos from 50 W to 4.5 kW and steppers from 0.37 Nm to 25 Nm, the MacTalk® tool is available. MacTalk® is the universal software from JVL for all integrated motor series: MAC motor®, ServoStep™ and QuickStep®. MacTalk® is used for setup, monitoring and diagnostics in real time - and for ePLC graphical program development, where the PLC program is embedded and runs locally in the motor.

The scope function in MacTalk® enables you to take a snapshot of selected values over a certain time frame. This is useful when commissioning a motor and also afterwards if you want to track an event, since the scope has access to all register values in the motor. You can choose between many trigger event types and setup the sample time etc. After an oscilloscope shot has been recorded it can be saved to local or network storage locations either as native

file or as an excel file for further analysis.

file or as an excel file for further analysis.

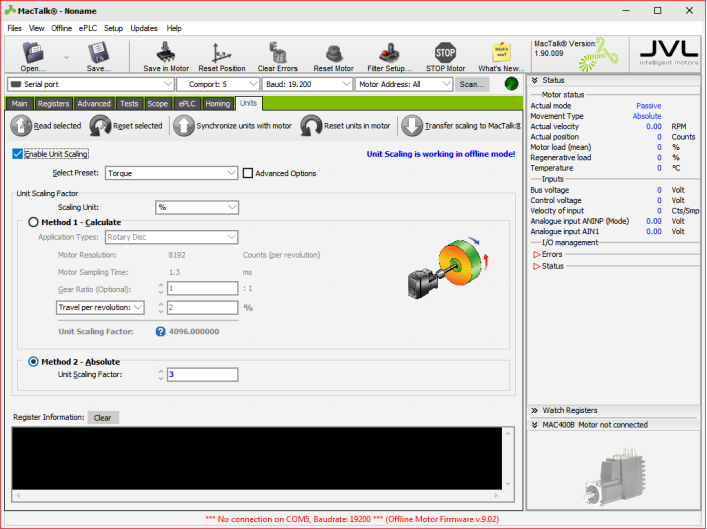

On-the-fly scaling is also available for newer motor types. MacTalk® helps you to set up the scaling of chosen registers and the motor will convert values on-the-fly between motor internal values and those preferred in your PLC or HMI.

The new Event Log tab shows the total operating time for the connected motor as well as the last 20 warning or error events: very useful for catching periodic or re-occuring error events.

Fig. 5. The MacTalk® software tool – Main window and oscilloscope window

Fig. 6. The MacTalk® software tool – unit scaling and example of watch-from-afar window

Further Advantages of JVL’s Integrated Motors

Apart from the many general advantages of using integrated motors, there are further advantages of using integrated motors from JVL.

• Wide Dual Series

As one of the few manufacturers of integrated motors, JVL offers both a full range of integrated stepper motors and a full range of integrated servo motors. Steppers range from NEMA size 17 to 43 with torque from 0.37 Nm to 25 Nm and servos range from 50 W to 4.5 kW RMS power.

• All Options in One Motor

You no longer have to choose one option at the expense of another: you can have all options in one motor! E.g. if you want integrated stepper motors you could have all this in one motor: closed-loop (based on incremental encoder) and absolute multiturn encoder and high IP rating and STO Safe Torque Off (TÜV approved) and industrial Ethernet onboard.

• All Ethernet Protocols in the same hardware

When a motor is equipped with Ethernet interface, using the same hardware it will be possible to switch between all major protocols: Profinet, EtherNet/IP, SERCOS, EtherCAT, Powerlink and ModbusTCP/UDP – and more as they

become available. As customer using our MacTalk® software you can change protocol free-of-charge as many times as you like.

become available. As customer using our MacTalk® software you can change protocol free-of-charge as many times as you like.

• Ingress Protection, IP

You can select either a standard IP rating of e.g. IP42 or higher protection like IP55, IP66, IP67 and even IP69K for selected motors.

For further information, please contact:

JVL A/S, Bregnerødvej 127, DK-3460 Birkerød, Denmark, Tel.+45 4582 4440, E-mail: jvl@jvl.dk, web:www.jvl.dk

JVL A/S, Bregnerødvej 127, DK-3460 Birkerød, Denmark, Tel.+45 4582 4440, E-mail: jvl@jvl.dk, web:www.jvl.dk

About JVL - JVL is a world leader within the development and production of efficient and compact integrated servo motors and integrated stepper motors. MAC motor® are a series of integrated brushless servo motors (up to 4500 W and 13.5 kW peak) and ServoStep™ are a series of integrated stepper motors (up to 25 Nm). Both motor series include motor, encoder, drive electronics, control electronics w/ePLC and optional Ethernet integrated into one compact unit. All major industrial Ethernet protocols like Profinet, EtherNet/IP, EtherCAT, Sercos, Powerlink and ModbusTCP/UDP are available.

JVL has more than 30 years of motion control experience and are well-known for their development and production of highly specialized integrated motors with industrial Ethernet and customized improvements. The close co-operation with customers and representatives result in cost-effective and technical optimized solutions for both basic and advanced motion control applications.

JVL's wide selection of quality products for motion control applications include: integrated brushless servo motors, integrated stepper motors, AC servo motor controllers, motor drivers (DC, AC and steppers), brakes, gear boxes and HMI touch panels.

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk