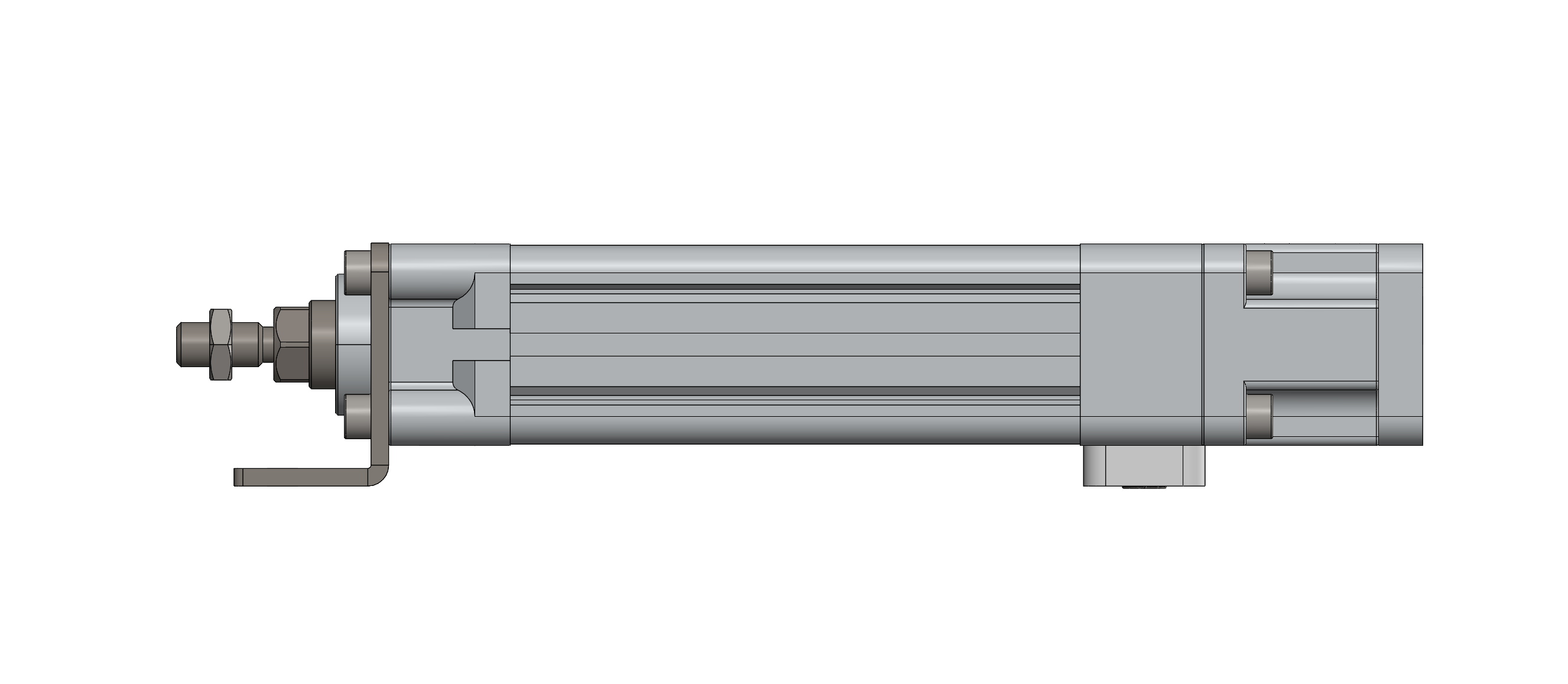

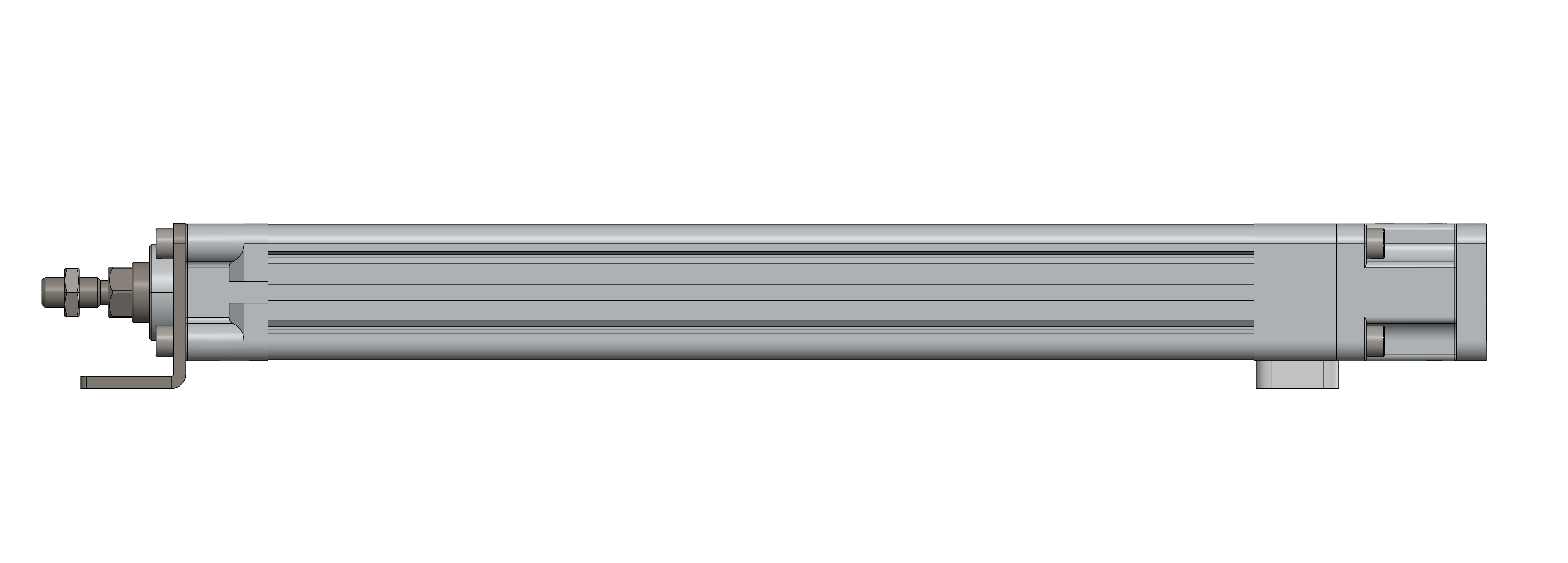

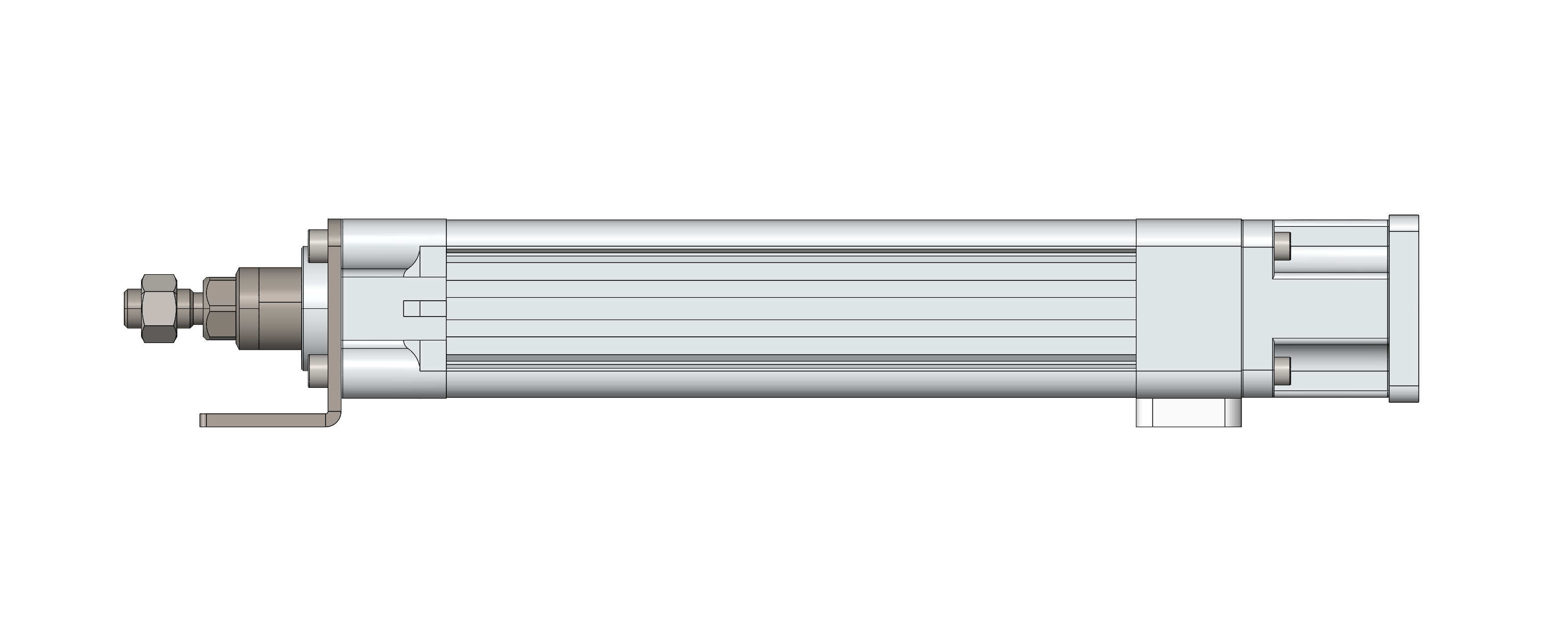

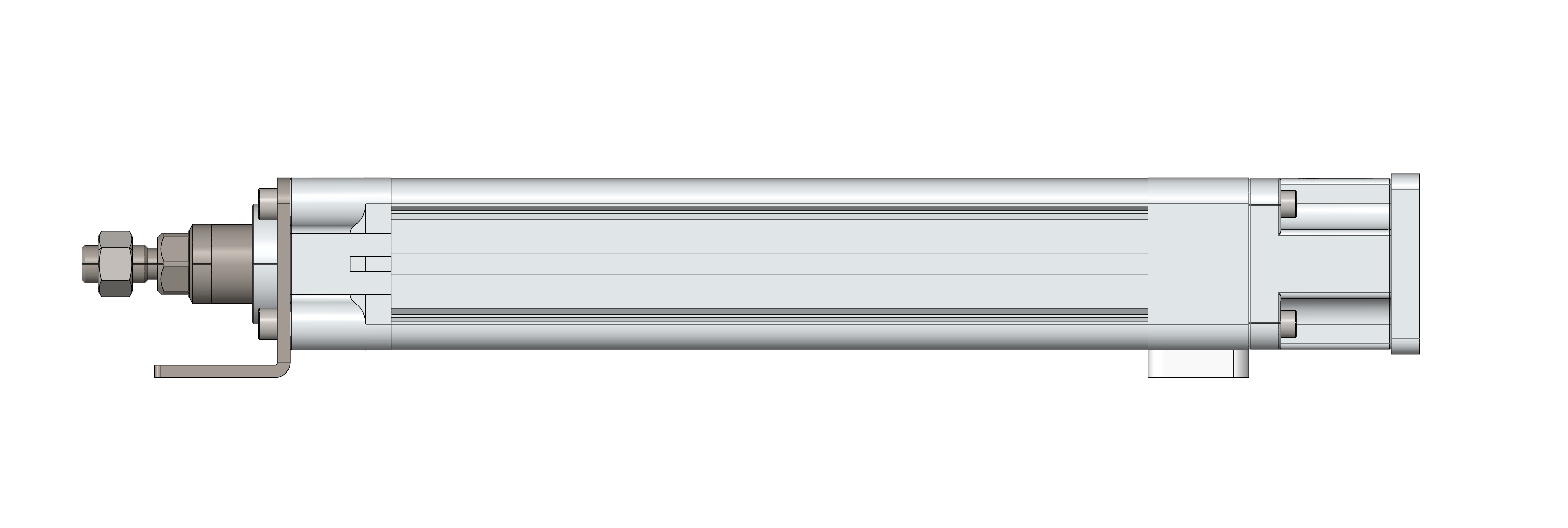

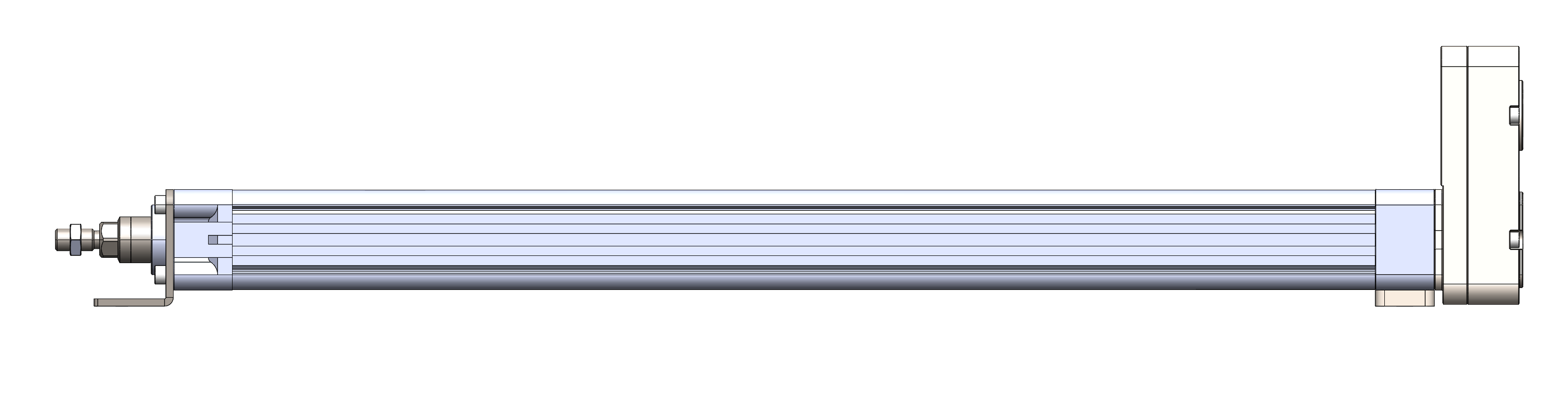

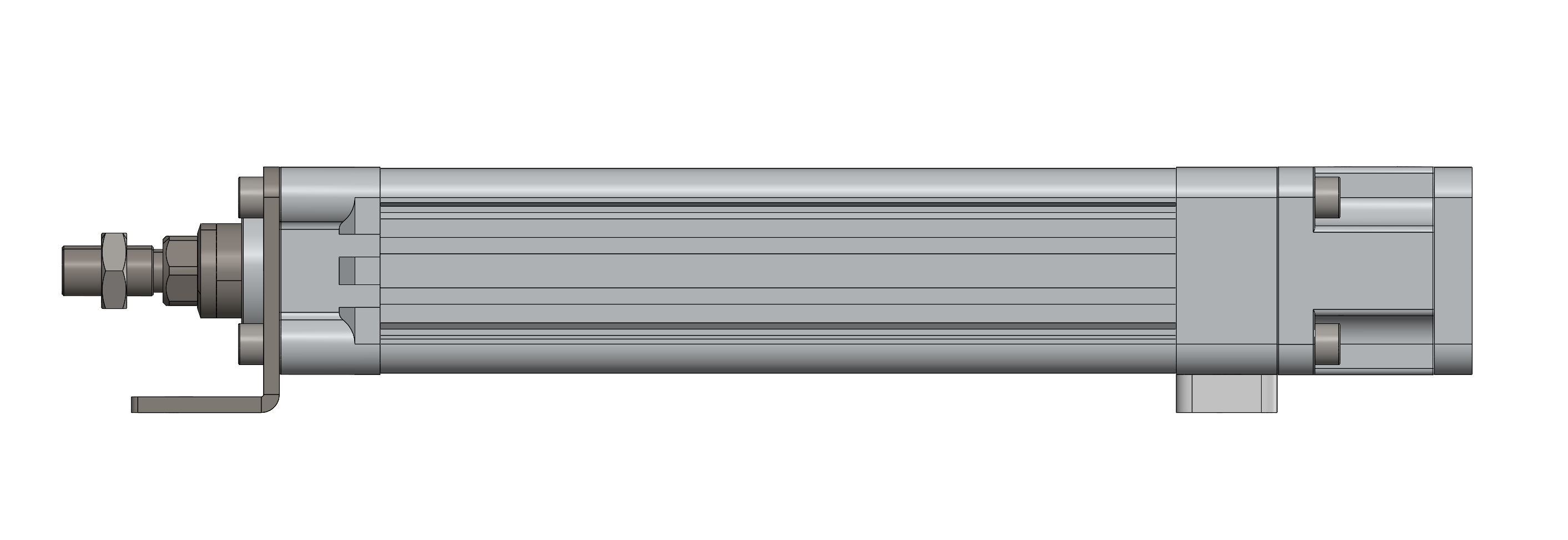

HBAC - Electric Cylinder Actuator

|

Electric Cylinder actuator with ball screw for NEMA17 and NEMA23 stepper or servo motors.

The electric cylinder is a mechanical linear axis with a rod piston. The drive component consist of a motor driver spindle screw which convert the rotary motion to the linear motion of the rod piston.

Features:

For OEM orders +25pcs can shaft diameter and housing be machines according to customer request. |

|

|

|

|

|

|

|||||

|

Under normal use, the guaranteed life is 10,000 km.

The use of inverted hanging can not be applied to the standard specifications. |

|||||

| Part number |

Size | Input motor shaft [mm]

|

mm/rev

|

|

Stroke

[mm] |

|

|

NEMA17

Stroke exceeds 150 mm, a deflection will occur, in this case please reduce the speed |

||||||

| HBAC46-RB35D4T2H050A |

Flange 47x47 mm |

Ø8 |

2.0 |

184 |

50 |

|

| HBAC46-RB35D4T2H250A |

Flange 47x47 mm |

Ø8 |

2.0 |

384 |

250 |

|

|

NEMA23

Stroke exceeds 300 mm, a deflection will occur, in this case please reduce the speed |

||||||

| HBAC55-RC03D4T2R100A |

Flange 57x57 mm |

Ø10 |

5.0 |

274 |

100 |

|

| HBAC55-RC03D4T2R300A |

Flange 57x57 mm |

Ø10 |

5.0 |

474 |

300 |

|

| HBAC55-RCX4D4TXR130A |

Flange

57x57 mm |

Ø12 |

5.0 |

304 |

130 |

|

|

NEMA23 Reverse parallel motor mount

Stroke exceeds 300 mm, a deflection will occur, in this case please reduce the speed |

||||||

| HBAC55-RN03D4T2R100A Reverse parallel motor mount |

Flange 57x57 mm |

Ø10 |

5.0 |

396 |

100 |

|

| HBAC55-RN03D4T2R500A Reverse parallel motor mount |

Flange

57x57 mm |

Ø10 |

5.0 |

794 |

500 |

|

|

Integrated Servo Motor MAC40x

Stroke exceeds 400 mm, a deflection will occur, in this case please reduce the speed |

||||||

| HBAC66-RE05D4T2W150A |

Flange 66x66 mm |

Ø14 |

10.0 |

317 |

150 |

|

| Accessories | Inner diameter [mm] | Outer diameter [mm] | Part number | Photo |

| Bushing adapter sleeves for motor, brake, gear, actuator |

5, 6.35, 8, 9.53, 10, 16 | 6.35, 8, 9.53, 10, 12, 14, 19 | Read more here |   |

| HBAC46-R... Coupling Ø8 |

HBAC55-R... Coupling Ø10 |

HBAC66-R... Coupling Ø14 |

|

| Technical data | |||

| Rod shaft thread |

M10x1.25, 22 mm long |

M12x1.25, 24 mm long |

M16x1.5, 32 mm long |

| Input shaft |

Ø8x24 mm |

Ø10x23 mm |

Ø14x23 mm |

| Sleeves |

See above table |

See above table |

See above table |

| Flange size |

47x47 mm |

57x57 mm |

66x66 mm |

| Input deep groove Ball bearing (type number) |

727: 7x18x6 mm |

7000: 10x26x8 mm |

7201: 12x32x10 mm |

| Mounting position (↑↓←→) |

Any |

Any |

Any |

| Recommended JVL Motors | MIS17x, MIS23, MAC083 |

MIS23x, MAC14x, MAC320 |

MIS23x, MIS34x , MAC40x |

| Mechanical data | |||

| Screw Spindle design | Rolled ball screw |

Rolled ball screw |

Rolled ball screw |

| Screw precision grade |

C7 |

C7 |

C7 |

| Max torsion angle of the piston rod degree | ±0.1 |

±0.1 |

±0.1 |

| Life time [km] (1) | 10,000 km | 10,000 km | 10,000 km |

| Lubrication (2) | Lubricated for life | Lubricated for life |

Lubricated for life |

| Spindle pitch mm/rev | 1, 2, 2.5 |

2, 4, 5, 10 |

5, 10, 16, 20 |

| Screw rod diameter | 8 mm |

12 mm |

16 mm |

| Max. stroke |

300 mm |

600 mm |

800 mm |

| Output range [N] |

Lead 1 mm: 425-5100

Lead 2 mm: 340-5100 |

Lead 5 mm: 1360-4080

Lead 10 mm: 680-4080 |

Lead 5 mm: 1360-6800

Lead 10 mm: 680-5400 |

| Max feed force | 2175 N |

6477 N |

8000 N |

| Velocity range [mm/s] |

Lead 1 mm: 40-200

Lead 2 mm: 50-250 |

Lead 5 mm: 80-250

Lead 10 mm: 80-500 |

Lead 5 mm: 50-250

Lead 10 mm: 60-500 |

| Max speed | 125 mm/s |

500 mm/s |

1000 mm/s |

| Max acceleration | 0.025 m/s |

0.15 m/s |

0.25 m/s |

| Max static axial force |

4000 N |

12000 N |

17000 N |

| Max rotational speed |

3000 RPM |

3000 RPM |

3000 RPM |

| Reversion backlash ball screw | 0.1 mm |

0.1 mm |

0.1 mm |

| Repetition accuracy |

±0.01 mm |

±0.01 mm |

±0.01 mm |

| No load detachment peak torque 200 RPM without rod sealing (IP42) |

0.32 Nm |

0.32 Nm |

0.64 Nm |

| No load driving torque 200 RPM with rod sealing (IP54) | |||

| Material |

|||

| End parts |

Painted die casting aluminum |

Painted die casting aluminum |

Painted die casting aluminum |

| Aluminium profile material |

6061-T6 |

6061-T6 |

6061-T6 |

| Weight |

|||

| Basic weight with 0 mm stroke kg* | 1.4 |

2.1 |

3.7 |

| Additional weight per 10 mm stroke kg* | 0.04 |

0.06 |

0.11 |

| Moving load with 0 mm stroke kg* | 0.263 |

0.577 |

1.025 |

| Moving load per 10 mm stroke kg* | 0.017 |

0.026 |

0.047 |

| Mass moment of inertia | |||

| With 0 mm stroke kgcm2* | 0.13 |

0.7 |

0.7 |

| Per meter stroke kgcm2/m* | 0.13 |

0.9 |

0.9 |

| Per kg working load kgcm2* | 0.0023 |

0.03 |

0.03 |

| Environmental condition | |||

| Ambient temperature °C | 0 - 40 |

0 - 40 |

0 - 40 |

| Storage temperature °C | -20 to +80 |

-20 to +80 |

-20 to +80 |

| Protection piston rod | Std. IP42. Optional IP65 | Std. IP42. Optional IP65 | Std. IP42. Optional IP65 |

| Protection cylinder | Std. IP42. Optional IP65 | Std. IP42. Optional IP65 | Std. IP42. Optional IP65 |

| Relative air humidity | 20 - 80 |

20 - 80 |

20 - 80 |

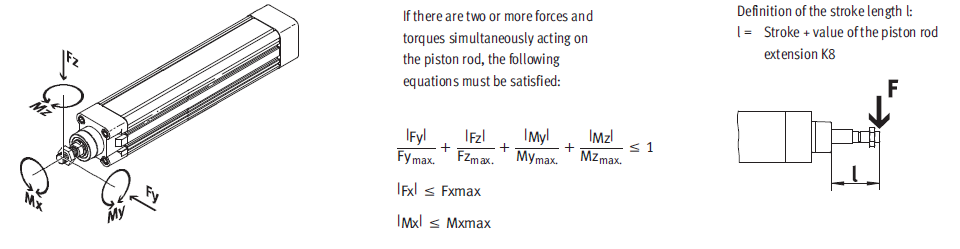

| Maximum permissible loads on the piston rod |

|||

| Fxmax static N | |||

| Mxmax Nm | |||

| Mymax, Mzmax | |||

| F (L=0 mm stroke) | 340 N |

340 N |

680 N |

| F (L=150 mm stroke) Value can be higher but depends on duty cycle, speed, acceleration etc. | 340 N |

340 N |

680 N |

| Standards |

|||

| Mounting dimensions corresponds | ISO21287 (20-25) and ISO15552 (32-100 ) |

ISO21287 (20-25) and ISO15552 (32-100 ) |

ISO21287 (20-25) and ISO15552 (32-100 ) |

| Withdrawn | ISO 6431, DIN ISO 6431, VDMA 24 562, NF E 49 003.1 and UNI 10290 |

ISO 6431, DIN ISO 6431, VDMA 24 562, NF E 49 003.1 and UNI 10290 |

ISO 6431, DIN ISO 6431, VDMA 24 562, NF E 49 003.1 and UNI 10290 |

Note (1): Please contact JVL for precise lifetime calculation based on actual load and conditions.

Note (2): For special purpose can optional grease pipe be mounted

Calculations:

Calculation of electric cylinder output force: F = T * 2 * Pi * R / L * N

F: Output force of electric cylinder [kN]

T: Motor output torque [Nm]

R: Transmission ratio

L: Lead of screw rod [mm]

N: Efficiency: Generally, the total efficiency of electric cylinder is 85%, but the efficiency will vary according to the actual use

Calculation of electric cylinder speed: M = [(v / 60) * L] / n

M: Linear speed of servo electric cylinder [mm/s]

V: Rated speed of servo motor [r/min]

n: Reduction ratio

L: Lead of screw rod [mm]

Calculation of service life of electric cylinder: L10 = (Ca / Fm) 3 * L = (Ca / Fm) 3 * (T * N * 2 * Pi * R / F)

L10: Service life of electric cylinder [km]

Fm: Average load borne by electric cylinder [kN]

Ca: Basic rated dynamic load of lead screw nut [kN]

L: Lead of lead screw [mm]

T: Motor output torque [Nm]

N: The total efficiency of electric cylinder, is 85%

R: Transmission ratio

F: Output force of electric cylinder [kN]

|

DETAILED |

|

|

|

DOWNLOAD |

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk